A fall into the self belay, even a small slip at the belay, quickly has fatal consequences. But at what exact height of fall does it actually become critical? And what influence does the sling material used have?

Self belay when climbing with static slings

We often use slings for self-belaying. Be it at the belay station for alpine or multipitch climbing, cleaning anchors during sport climbing or for resting in the via ferrata. In contrast to dynamic kernmantle ropes, slings are designed for static loads. You have to be aware of this, because in use this has decisive consequences.

Falling into static slings can quickly become problematic. The material is not designed to absorb dynamic loads. Even a fall from a relatively low height can lead to failure.

Experimental setup: We bring the practice into the lab

To determine the critical falling heights at which the system fails, we set up a scenario and tested different heights and materials. For this purpose, the different self belay slings were fixed to an anchor point by means of carabiners (simulation of abseiling) and connected to a fall mass (80 kg) by means of a bowline in tie-in point. The slings were sewn slings according to EN 566 with a minimum breaking strength of 22 kN and a length of 120 cm. The falling mass was triggered from different heights and the height at which failure occurred was determined. The heights were increased in 10 cm steps and the height at which failure of the sling occurs was named as the critical falling height.

The results of the fall tests

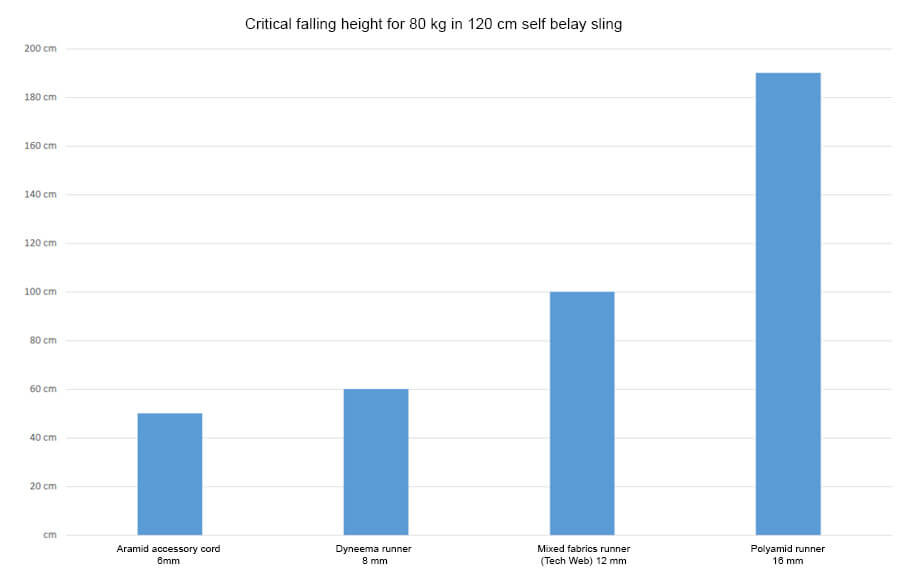

The 6 mm diameter aramid sling failed at a fall height of 50 cm, the 8 mm wide Dyneema sling at 50 cm, the Tech Web mixed fabric sling at 100 cm and the 16 mm wide polyamide sling at 190 cm. The sling either broke at the bowline knot or the tie-in point in which the sling was knotted.

BU: Falling height, with a weight of 80 kg, at which a self belay sling (120 cm length) with bowline in the tie-in point breaks. Different materials are shown.

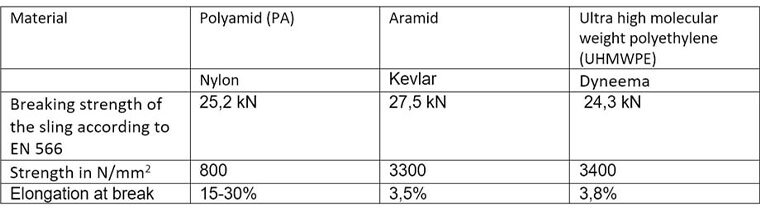

In summary, it can be seen that Dyneema and especially Aramid slings fail significantly faster than Polyamide slings. This difference can be explained by the significantly lower elongation at break of Dyneema and Aramid compared to Polyamide (see table 1). Polyamide stretches significantly more until the breaking strength is reached than Aramid and Dyneema and thus absorbs energy until it breaks. However, the impact force figures for Polyamide also increased very quickly to a level that is incompatible with the human body.

It can therefore be generally stated that the application of dynamic loads in the self belay sling is always problematic and must be prevented.

So what should be considered when using self belay slings?

It is important to always keep your sling under load (i.e. under tension). This prevents dynamic load application. If, for example, it is necessary to go beyond the abseiling point (when one end of the rope is caught above it), you should either belay with a dynamic rope or use a fall absorber such as the EDELRID Absorber Sling as a self belay sling.