Ropes are to be used. However, every use leaves traces on the rope. Therefore, before and after each use, your climbing rope should be checked for possible damage. In addition to visual inspection, it is essential to let the rope run through your hands regularly. Only this haptic inspection can detect non-obvious deformations and damages inside the rope. In case of serious incidents (impact from a fall, etc.) the rope must be inspected with particular attention.

In general, if the user is unsure for any reason, the rope must not be used anymore or must be checked by a PPE expert.

For reasons of traceability, it may be useful to keep a record of the age and use of the equipment. This simplifies the inspection and provides additional assurance for the problem of non-visible damage.

IN THE FOLLOWING WE WILL THEREFORE GO THROUGH THE INSPECTION PROCEDURE FOR KERNMANTLE ROPES:

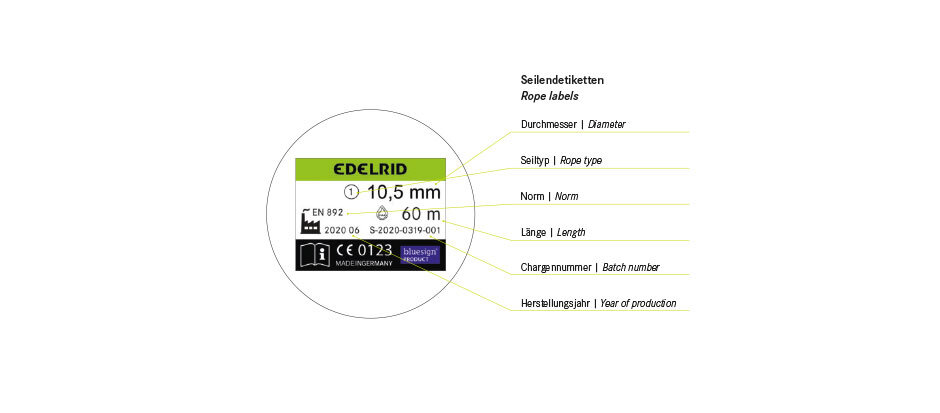

1. Checking of the marking and maximum service life:

First of all, we make sure the CE mark and serial number are present and readable and check if the maximum product lifespan has not been exceeded. For this purpose, the year of manufacture of the rope is required. Information on the maximum product lifespan can be found in the manufacturer's user manual. This is supplied with the rope at purchase or can be downloaded from the manufacturer's website.

If there is no marking anymore or if the maximum product lifespan has been exceeded, the product must be discarded.

2. Check of the correct rope length and middle marking:

We check if the indicated rope length is correct and if the middle marking is in the right place. To easily determine the rope length, the rope can be doubled twice and the measured value multiplied by 4.

3. Visual inspection of the rope's heath:

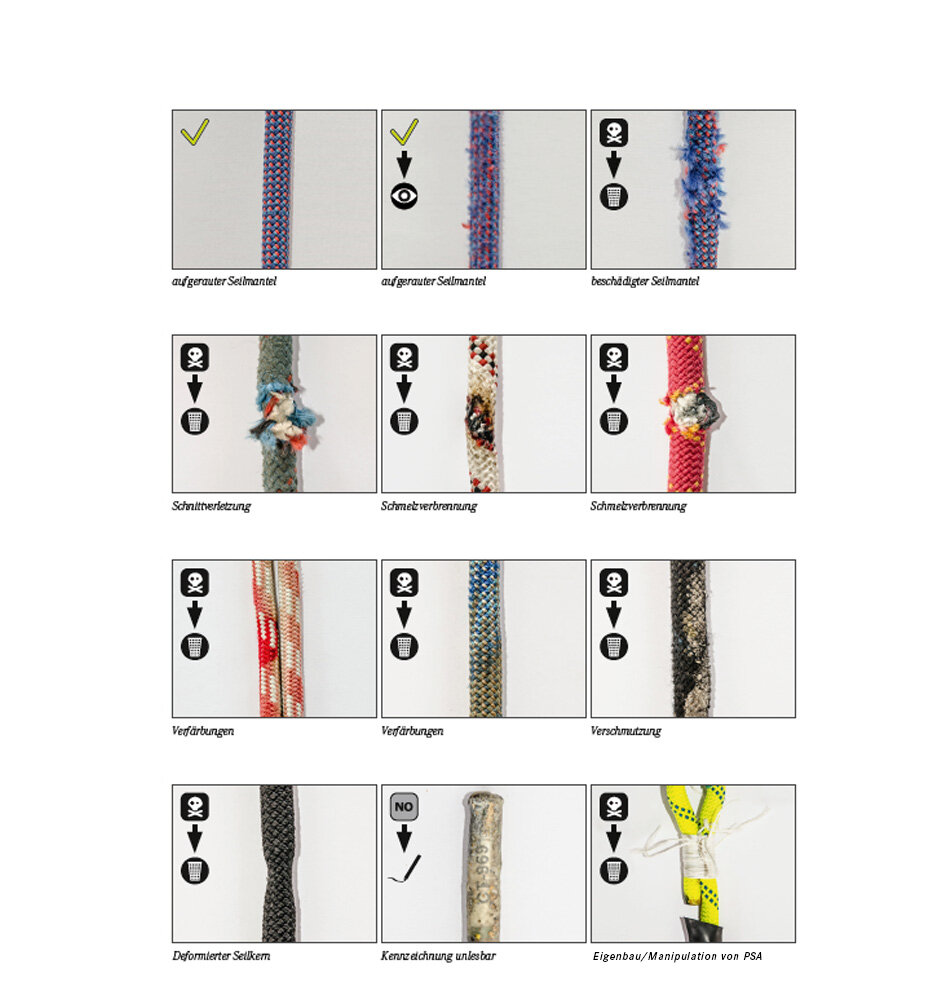

The visual inspection of the rope sheath is intended to reveal mechanical damage such as cuts, abrasions, burns, hardening, discoloration or sheath displacement. Cuts mean damage to the rope, burns or hardening indicate thermal stress and discoloration can be an indication of the effects of chemicals. In all cases the product must be withdrawn from circulation.

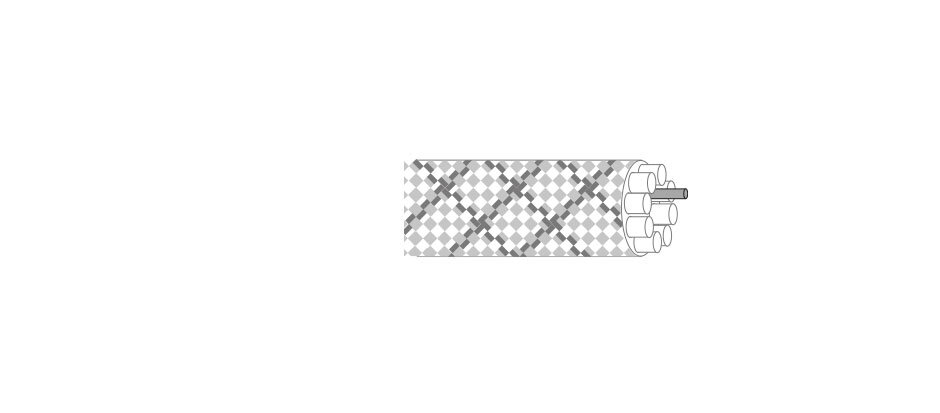

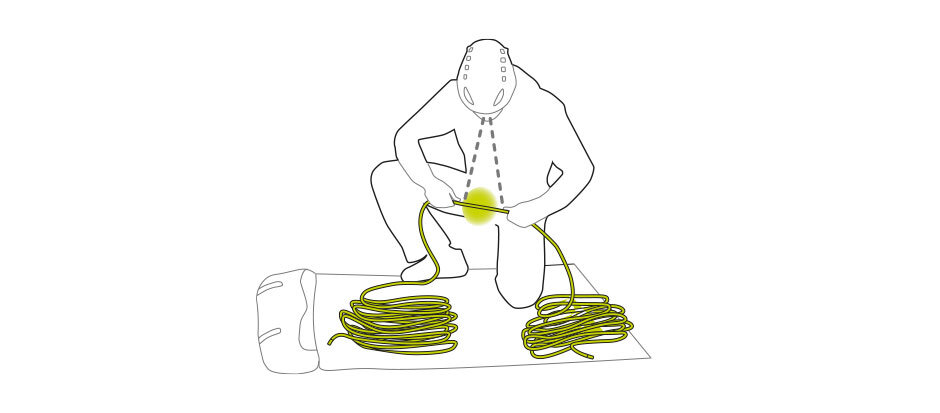

4. Haptic inspection of the rope's core:

Now the core is inspected by hand over the entire length of the rope. To do this, let the rope slide completely through both hands in a slight curve. Can you feel stiff or soft spots or are there unusual thickenings? Deformations or bruises indicate areas where the core is damaged or degenerated. In such a case, the product must be discarded.

Some examples of rope damage: