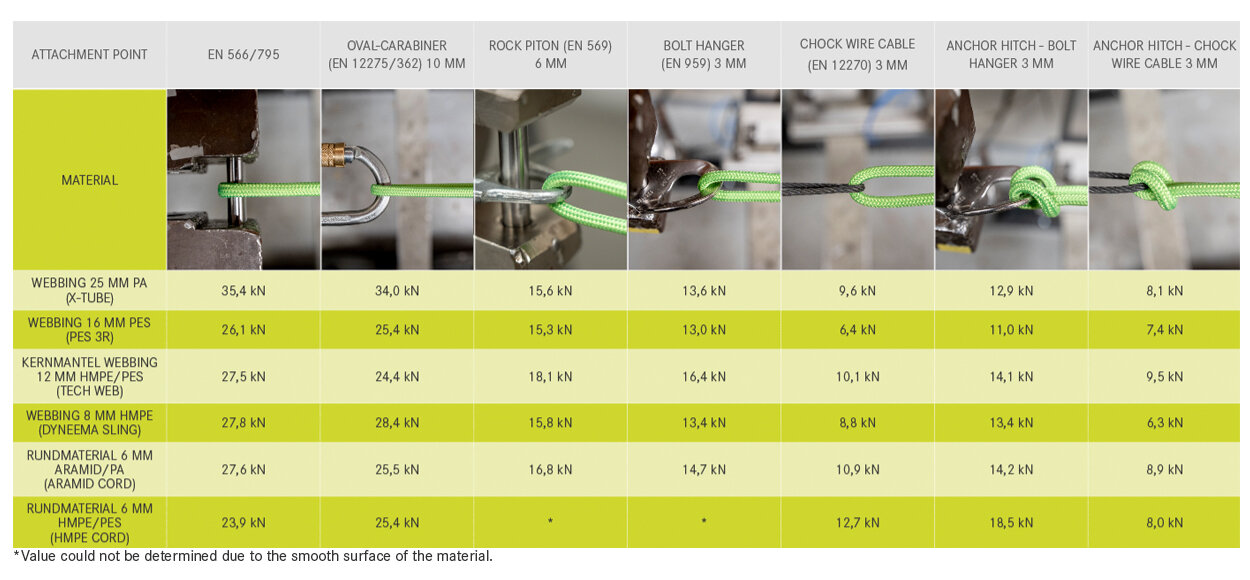

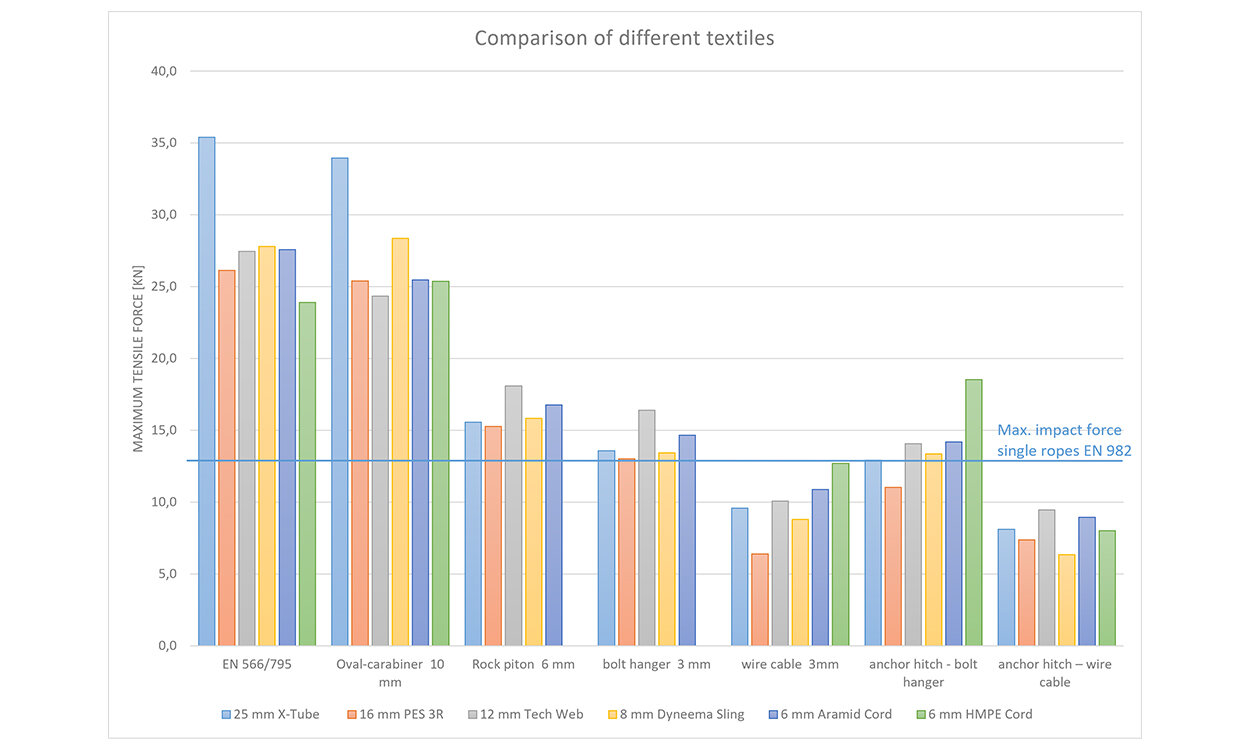

The influence of small metallic deflection radii on the strength of textile slings according to EN 566/795 was investigated. Tensile tests show that the standard strength is only achieved with deflection radii ≥ 10 mm. Carabiners usually cause only minor reductions, depending on size and geometry. Significantly greater strength losses occur with small radii such as bolt hanger, wire cables, especially when connected with an anchor hitch knot. With decreasing radius and uneven contact, the maximum tensile force decreases significantly.

In mountain sports and occupational safety, the question often arises as to whether textile slings can be threaded directly through metal anchor points or whether carabiners are required to protect the textile. The aim of this study is to systematically quantify the influence of small deflection radii from different anchor points on the maximum tensile force of textile slings.

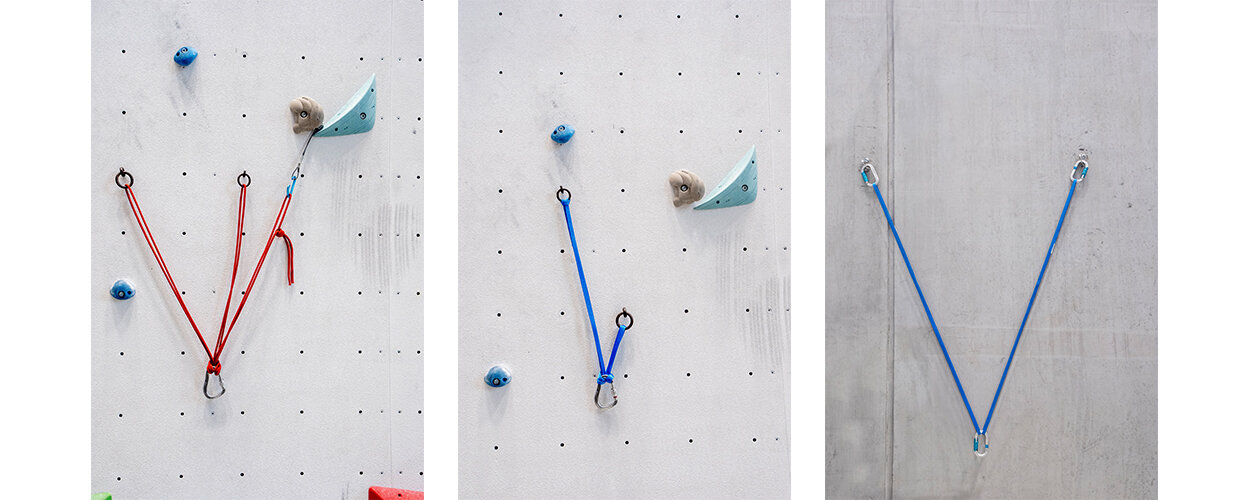

Picture: Examples of connections between anchor points and textile slings in mountaineering and occupational safety.

Method

The tests were carried out on a tensile testing machine at a speed of 500 mm/min. The standardised test according to EN 566 and EN 795, in which slings are loaded via two steel bolts with a diameter of 10 mm, served as a reference. Identical textile slings were then passed through different metal attachment points (carabiners, bolt hangers, chock wire cables, anchor stitches). A 25 mm wide polyamide sling (X-Tube), a 16 mm polyester sling (PES 3R Sling), a 12 mm sling with HMPE core and polyester sheath (Tec Web Sling), an 8 mm HMPE sling (Dyneema Sling), a 6 mm sling made of round material with an aramid core (aramid cord) and a 6 mm sling made of round material with an HMPE core. The maximum tensile forces determined were compared with the reference.

Discussion

The results clearly show that textile slings only achieve their declared strength when loaded over deflection radii of at least approximately 10 mm. As the radius decreases and the contact surfaces become non-parallel, the reduction in strength decreases significantly. Depending on their geometry and size, carabiners usually only cause minor reductions, while directly threaded small metal radii (e.g., bolt hangers or chock wire cables) massively reduce the maximum tensile force. A anchor hitch knot represents an additional weakening factor. Wider slings are more sensitive to unfavorable geometries. There are differences between the materials, but the tendencies of the weakening effects are very similar. The results are examples that illustrate the magnitude of the weakening effects. The exact reduction depends on the exact geometry of the deflection point.

In practice, this means that the decision as to whether an anchor point can be threaded directly or whether it is better to use a carabiner/connecting element depends on the required strength. In mountaineering, for example, forces exceeding 12 kN (maximum impact force of ropes according to EN 982) must be ruled out, and forces exceeding 7 kN are not to be expected. It is therefore common practice to thread rock pitons in accordance with EN 569 directly at alpine belay stations, but to use carabiners to connect textile slings in chock wire cable in accordance with EN 12270. This is based on a balance between strength requirements and the weakening effects of anchor points. It should be noted that new slings were used in the tests. Aging effects can reduce the initial strength of textiles and further increase the weakening effects of small radii at attachment points.