-

bluesign

Quality and safety are the key factors that have been driving us further since the very beginning. When making responsible and innovative high-performance ropes we also consequently have been following the maxim of sustainability. This is why EDELRID has set new industry benchmarks for sustainable rope production.

We are the first rope manufacturer to adapt our ropes to meet the tough demands of the Swiss bluesign System. It is the most stringent environmental standard for the production of textile products: independent, internationally recognised and based on the five principles of resource productivity, consumer safety, water emission, air emission as well as occupational health & safety.Our ropes carry the bluesign PRODUCT label thanks to their combination of certified source materials and our advanced rope production facilities in Isny.

The bluesign PRODUCT label is a seal of quality: It guarantees an eco-friendly manufactured product that is low in pollutants and safe for health and the environment. As such, we have responded to the natural demands of our customers for safe, environmentally friendly and sustainable products.

Eight years of working together with bluesign technologies ag in Switzerland, allow us to draw on in-depth experience of sustainable rope production. By converting all our rope production to the tough demands of the bluesign System we were able to make the following efficiencies when dyeing sheath yarns:

62 %CO2 reduction89 %savings in water63 %less energy consumption63 %less chemicals -

Upcycled

We always try to avoid waste and leftovers in our production. If this is not possible, the material is melted down or otherwise reprocessed, for example in the form of material carabiners, backpacks or belts.

-

Recycled

Recycled raw materials are used for this product. For example, plastics are returned to the recycling loop and reused.

-

Climb Green

With our #ClimbGreen collection, we want to prove that sustainability can also be consistently implemented in the field of PPE without compromising on safety or performance. All #ClimbGreen products follow the principle of the 3R´s: REDUCE, REUSE, RECYCLE. Each product is unique in its own way. Together they form the core of the EDELRID #ClimbGreen collection.

-

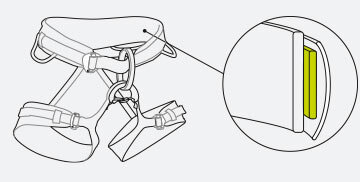

RFID inside

EDELRID offers a range of products with integrated RFID transponders. Furthermore, all PPE products can be retrofitted with our RFID transponders. The transponders are small, robust and specially designed for use with PPE products.

-

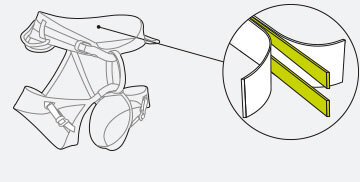

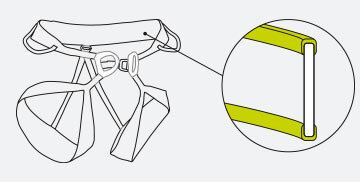

Indicator webbing

Webbing with internal wear indicator made of red polyester fibers. In the event of excessive wear a red wear indicator warning thread becomes visible – alerting the user that the product should be replaced.

-

Failsafe 180°

Bypass-save shock absorber (180° incorrect use): When using conventional Y-shape lanyards, there is a risk of the lanyard’s shock absorber being ‘short-circuited’ if the second lanyard arm isattached to a load-bearing section of the full body harness (e.g. a position eyelet). After a short braking distance, the connector becomes static, resulting in a significantly higher risk of extremely serious injuries. In the worst case scenario, the high forces applied to the seam between the two arms as a result of the 180° incorrect use can cause the lanyard to tear at this point. This would result in a complete fall. Thanks to an innovative design, the shock absorbers on the most EDELRID lanyards with two arms are fully functional even in the event of 180° incorrect use. The patented design also works without restriction if the load-bearing arms are ‘short-circuited’. This means that the second lanyard arm can be attached to the load-bearing elements on the full body harness. All EDELRID products that are 180° fail-safe are labelled with this symbol.

Ropes

-

Single rope

Single ropes are the most common type of climbing rope. They are the classic climbing rope, as it were. Single ropes come in different lengths and diameters and cover a range of different applications. They are classic sport climbing ropes, for both outdoor and indoor use, and are also used for alpine climbing and mountaineering and by big wall climbers. One of their main advantages is their simple and uncomplicated handling. EDELRID manufactures single ropes in diameters from 8.9 mm to 10.5 mm. They weigh in at 52 to 69 grams per metre. Single ropes with a thicker diameter are generally stronger and can withstand a greater number of falls. However thicker also means heavier. For intensive use, such as working routes or top-roping, there are robust single ropes with a higher sheath proportion.

-

Twin rope

Twin ropes must always be used in pairs. They only offer standardised safety when used as a pair. It is important that twin ropes are always clipped together into each bolt or piece of protection. They have a lighter weight and a thinner diameter. Twin ropes offer greater safety reserves due to increased redundancy that comes with using two ropes. Twin-rope techniques also provides increased safety due to their significantly greater sharp edge resistance as well as reducing the risk of a total failure (stonefall, breaking over a sharp edge). This is why twin ropes are particularly suited to alpine climbing in demanding terrain or for ice and mixed climbing. Using twin ropes also allows you to abseil twice as far, which means that you can escape from a wall quicker. Twin ropes normally have a diameter of 6.9 to 8 mm and weigh around 40 grams per metre.

-

Half rope

Half ropes (also known as double ropes) are designed, like twin ropes, to be used as a pair. The same as twin ropes they also only offer standardised safety when used as a pair. However, unlike twin ropes, half ropes do not need to be clipped together into each bolt or piece of protection. This technique is ideal for poorly protected or zig-zagging routes or for traditional climbing (trad). It allows rope drag to be reduced where protection points are spread out and considerably reduces impact force. It follows that climbing with a pair of half ropes requires using a belay device that allows you to manage two ropes simultaneously, i.e. to be able to pay out and take in both ropes. Half ropes are used for the same activities as twin ropes. They have one important difference – half ropes can be used as a single rope to bring up a second. This is particularly relevant when climbing as a party of three and bringing up two seconds. Half ropes range in diameter from 7.5 to 9 mm and generally weigh from 40 to 50 grams per metre.

-

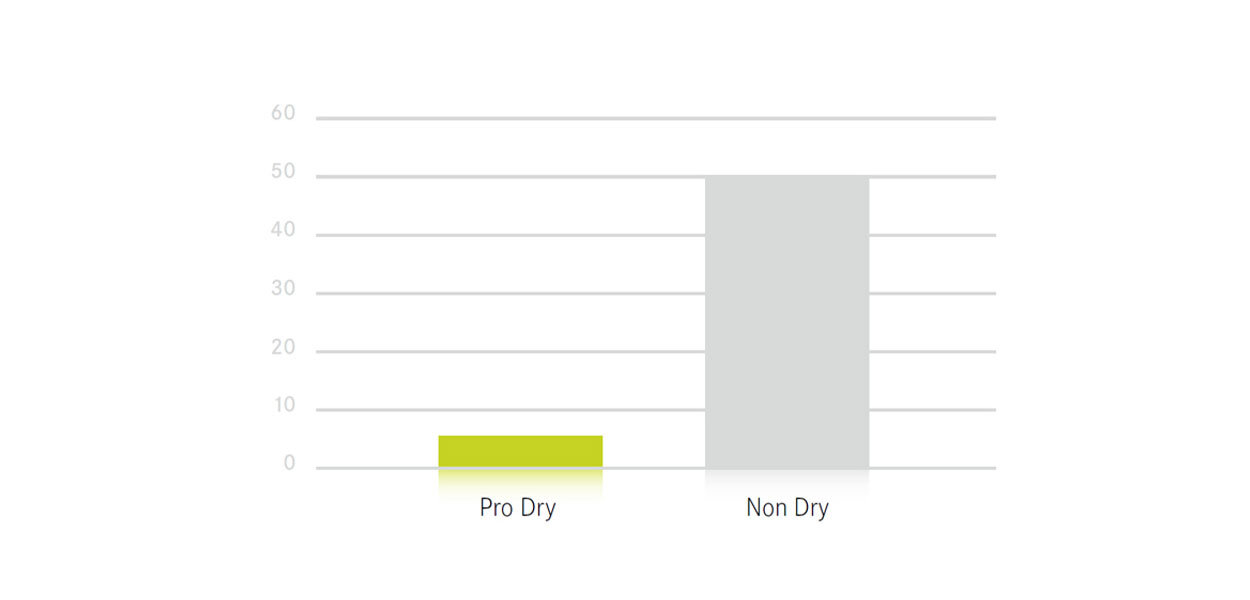

Pro Dry

Untreated ropes can absorb up to 50 % of their own weight in water. When wet, such ropes become extremely heavy, difficult to handle and may freeze in cold conditions. Moreover, their safety reserves are compromised. This is why dry treated ropes are used for activities where ropes are more likely to get wet, such as ice climbing or mountaineering. Pro Dry is a new finishing process, which provides a solution to this problem. First the core yarns are infused. Then, once braiding is completed, the finished rope (core and sheath) is infused again. In a final stage, the dry treatment is thermally fixed. The result is a rope that is durably water repellent and dirt resistant. Pro Dry ropes are particularly quick drying, absorb virtually no water and are resistant to freezing in cold temperatures. Due to their minimal water absorption (1–2 %) in accordance with the UIAA water-repellent test, Pro Dry ropes hardly increase in weight. As such, they continue to perform well and provide high safety reserves even in wet conditions.

UIAA WATER-REPELLENT TEST

The UIAA water-repellent test is a new standard and test developed by the UIAA to measure the water repellency of ropes. During the test, a rope sample is first subjected to mechanical surface abrasion over its entire length. This simulates the wear a rope is exposed to in practice on rock and ice. In a standardized procedure, the rope sample is then fixed to a slanted table and undergoes a defined water flow (2 l/min) for 15 minutes. The rope sample is weighed before and after the water flow. Finally the difference between these two values is calculated and expressed as a percentage. The amount of absorbed water must not be greater than 5 % of the rope sample's weight. Ropes that meet these requirements may be labeled as UIAA Water Repellent.

PRO DRY BENEFITS AT A GLANCE

IMPREGNATED CORE AND SHEATH:

- water absorption equal to only 1–2 % in accordance with the UIAA water-repellent test

- durably water-repellent and dirt-resistant

- high abrasion-resistance

- outstanding performance in cold and wet conditions

- narrow diameters for less weight per meter

- optimal gliding characteristics

-

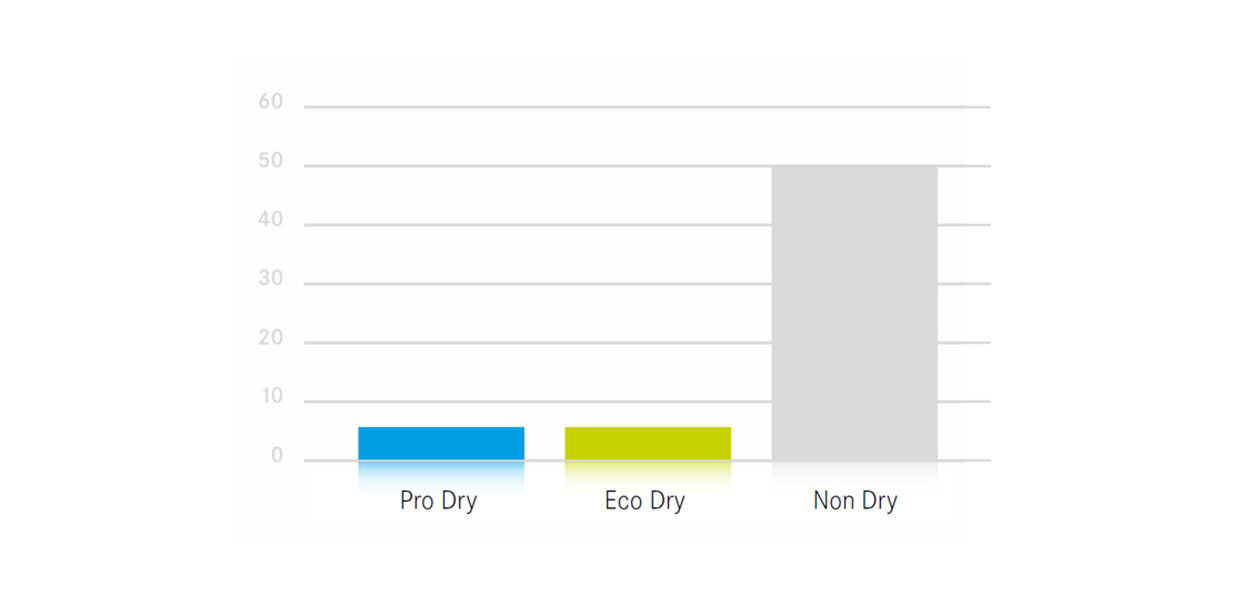

Eco Dry

Poly- and perfluorinated chemicals (PFCs), and their subcategory PFAS in particular, make outdoor equipment resistant to oil, grease, and water. Once released into the environment, however, the chemicals degrade very slowly, posing a long-term environmental problem. With Eco Dry finishing technology, we have succeeded in developing a process that is almost on a par with high-performance PFCs and PFAS. Due to their three-dimensional kernmantle construction, the treatment process of ropes is very complex. This is because the finishing process must never compromise the safety and functionality of a climbing rope. The Eco Dry process meets all these requirements and is 100% free of PFCs and even PFAS. The world's first PFC- and PFAS-free rope that also meets the UIAA water repellent standard is the EDELRID Swift Eco Dry 8.9 mm. It absorbs less than 1 to 2% of its own weight in water. It is also bluesign® certified and offers comparable values to the Pro Dry line in terms of durability, abrasion resistance, and water and dirt resistance.

UIAA WATER-REPELLENT TEST

The UIAA Water Repellent Test makes the water-repellent properties of ropes measurable. The test samples are first subjected to a mechanical abrasion test, as occurs in practice in the use in rock and ice. Subsequently, the test sample is watered according to a standardized method in a defined time and with a defined amount of water. The proportion of absorbed water must not be more than 5 % of the self-weight of the rope. Ropes meeting these requirements may be designated as "UIAA water epellent".

ECO DRY BENEFITS AT A GLANCE

IMPREGNATED CORE AND SHEATH

- water absorption equal to only 1–2 % in accordance with the UIAA water-repellent test

- 100 % PFC-free

- durably water-repellent and dirt-resistant

- high abrasion-resistance

- outstanding performance in cold and wet conditions

- narrow diameters for less weight per meter

- optimal gliding characteristics

-

Color Tec

An innovative braiding process for making bicolor ropes. The woven design of the rope completely changes when it reaches the middle. This provides a permanent and distinctive middle marking. We use this technique exclusively for ropes in our Pro Line. During braiding, the bobbin order of the sheath yarns alters on the braiding machine automatically at the middle of the rope. The design then changes so that two rope halves of the rope are easy to distinguish. The ColorTec braiding process makes both color and design changes possible.

COLOR TEC BENEFITS AT A GLANCE

BRAIDING TECHNIQUE FOR BICOLOR ROPES

- both color and design changes possible

- unmistakable design

- two distinct rope halves ensure permanent middle marking

- two braiding circles

-

Cut Protect

GIVE SHARP EDGES THE COLD SHOULDER

The development of a new braiding process and the combination of high-strength aramid and polyamide fibers allow us to produce ropes with a high cut resistance.

While problems such as acid contact and friction burns can be excluded as far as possible through proper application and storage, edge loads are still a problem.. The edge does not even have to be particularly sharp.

It becomes particularly problematic when there is a pendulum movement over an edge (e.g. when abseiling or lowering). Then, in addition to the edge load, a cutting load occurs, which can have fatal consequences. The rope is cut through, so to speak. How can we mitigate these risks?

At EDELRID we have tackled the problem and developed a rope that has a particularly high cut resistance. This is made possible by the new "Cut Protect" rope technology. This means high-strength aramid fibers are braided into the rope sheath during the braiding process. Compared to polyamide, aramid has a significantly higher cut resistance.

THE CRUX:

aramid is a particularly static material. Compared to polyamide, it has virtually no dynamic properties. However, in the event of a fall, it is necessary to absorb the resulting energy and thus reduce the impact force to a tolerable level.

Since the current standard for dynamic mountain ropes does not include a test procedure for assessing the cut resistance, at EDELRID we have developed a special machine that simulates this load under laboratory conditions. The internal comparison of the Swift Pro Dry and the Swift Protect Pro Dry shows that ropes with Cut Protect technology have

almost twice as much cut resistance as conventional mountain ropes.

-

Duo Tec

A patented braiding process developed by EDELRID for the production of bicolor ropes. The two halves of the rope are clearly distinguishable due to a change in pattern halfway along the rope. The middle of the rope can always be clearly identified, which is a great advantage especially when abseiling, coiling a rope, or estimating how much rope you have left. This change in design is achieved by a bicolor strip woven into the sheath. On reaching the middle of the rope, the strip automatically switches from one side (e.g. green) to the other (e.g. black). This gives the rope a permanent center mark.

DUO TEC ADVANTAGES AT A GLANCE

BRAIDING METHOD FOR BICOLOUR ROPES

-

only change of design possible

-

braided tape (two colours)

-

permanent centre detection

-

-

Thermo Shield

Thermo Shield is the basic treatment that we apply to all our ropes to ensure they have the renowned EDELRID suppleness. The treatment involves a thermal process that perfectly aligns the core and sheath yarns. A special heat treatment relaxes then shrinks the rope’s fibers. This harmonizes the gliding characteristics of the yarns inside the rope, making it supple and compact. The result is the creation of ropes that will neither shrink retrospectively nor quickly become stiff.

THERMO SHIELD ADVANTAGES AT A GLANCE

THERMAL REFINEMENT

- Suppleness

- compactness

- longer service life

- no post-shrinkage

-

Lap Coil

The 3D lap coiling technique makes uncoiling the rope for the first time unnecessary. We extended our production site with a specially developed lap coiling machine that winds up our ropes. In combination with the thoughtout design of the packaging provided with every EDELRID rope, it has now become super easy to instantly start your climb using your new rope: You do not have to do more than pulling it out! The marking on the rope as well as a detailed description on the packaging additionally ensure that you do things right and can use the full potential of the rope without annoying twisting and tangling.

-

Link Tec

This procedure bonds together the core and sheath during the braiding process to minimize sheath slippage and significantly increase the rope’s service life. We have always used this technology for our climbing gym ropes, which have to withstand the intensive, prolonged loads of top-roping.

-

Sync Tec

In contrast to conventional kernmantle ropes, Sync Tec technology ropes have a permanent, mechanical connection between core and sheath. During the braiding process, the core and sheath are braided together at constant intervals. Compared to chemical connections (e.g. using adhesives), which can break down over time, the Sync Tec connection is permanently stable. Core and sheath form a unit, which leads to a better force distribution between the individual fibers. This makes Sync Tec ropes particularly compact, dimensionally stable and pleasant to handle. In addition, the permanent connection of core and sheath prevents the sheath from slipping off the core in the event of damage to the sheath (e.g. due to a sharp edge), which is an additional safety feature. These properties make Sync Tec ropes the first choice for demanding high altitude and rescue operations, where an additional safety margin is desirable.

Harness

-

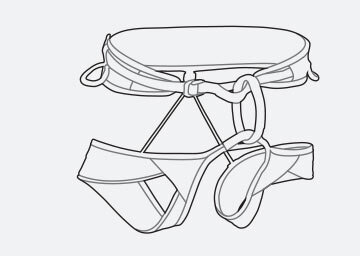

3D Vent

The 3D Vent technology harnesses offer widespread load transmission, ergonomic fit and good breathability. Our 3D Vent harnesses are among the most comfortable harnesses on the market. High-quality padding reinforced with homogeneous stitched webbing ensures even load transmission over all areas of the harness. The three-dimensional form of the leg loops are anatomically shaped to fit the human body. The robust three-layer foam padding retains its shape even when subjected to pressure. The perforations in the foam allow body heat and perspiration to escape.

-

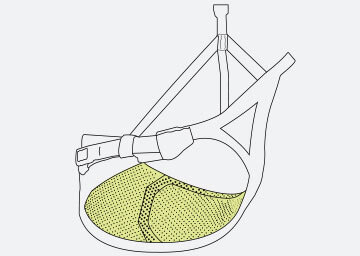

3D Vent Lite

Our 3D Vent Lite series harnesses have an innovative, super-light design for excellent support and maximum freedom of movement. They combine minimal weight and a small pack size with superior comfort to wear, climb or hang in. How do we do this? By integrating high-strength HDPE (High Density Polyethylene) webbing tape in the waist belt and leg loops. This ensures that the load is spread over the entire harness without adding bulk. In addition, the air permeable support fabric is made of monofilament yarns, which allow body heat and sweat to escape.

-

3D Pad

An evolution that makes our climbing harnesses even more comfortable without increasing their weight or pack size: with the 3D Pad technology, padding is minimized to strategically useful places, where it is intensively used. This provides outstanding support and comfort as well as optimum force distribution in the precise places where loads occur. The uniform and flat force distribution is supported by several homogeneously distributed straps. Thanks to the ergonomic cut with 3D-shaped waist belt and leg loops, pressure points and cutting in are prevented. The use of essential padding only helps to ensure a low overall weight and compact pack size. The light, 3-layer foam remains dimensionally stable even under load. The gaps are particularly breathable, enabling body heat and perspiration to be optimally released.

-

Soft Frame Construction

This technique is mainly used with our alpine harnesses, as the balance between the factors of comfort, weight and pack size is decisive here. The challenge is not to neglect any of these factors. The use of two load-bearing straps distributes the force over the entire width of the waist belt, which increases support and comfort enormously. At the same time, this construction improves breathability. Due to the wide force distribution, thick padding is not necessary. This results in low weight, a flat design and a minimum packing size, combined with a high level of comfort.

-

Center Fit Construction

The harnesses in our Center Fit series are particularly comfortable all-rounders. Their construction combines strong, load-bearing webbing with 3D Mesh padding, making them significantly more comfortable. The moveable foam padding can be adjusted. This means that the tie-in point can be centered and the gear loops aligned for all waist sizes. Inverse edges at the top of the waist belt prevent pressure points and provide increased comfort when hanging.

-

Light Frame Construction

Harnesses made with a load-bearing edge binding construction are particularly lightweight. The edge binding runs throughout the entire harness, so that it safely carries the load around both the hips and the legs. Weight is proportionately distributed from the webbing to the padding. Combined with perforated foam and mesh fabrics, it’s possible to make extremely lightweight harnesses with exceptional breathability. We mainly use this technology for our ultra-light sport climbing and ski touring harnesses.

Helmet

-

Wing Fit

Innovative closure system with rear adjustment dial. The webbing cradle can be quickly adjusted to fit all head shapes by turning the dial. During transport the cradle tucks away into the helmet.

-

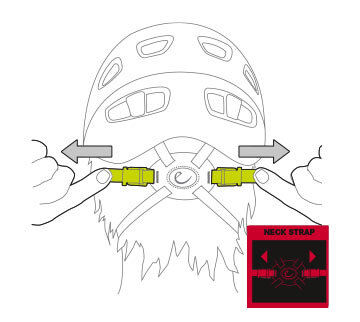

Neck Strap

The head and neckstrap are fully adjustable via two clip buckles. Designed to provide a perfect fit, minimum pack size and excellent ventilation. The straps tuck away into the helmet during transport.

-

Curv®

Curv® is an outstanding material that combines the versatility of a 100% thermoplastic with the high performance of a fiber-reinforced composite. Parts made with Curv® exhibit high stiffness, high tensile strength and outstanding impact resistance. At the same time, they are extremely light and can be molded thermoplastically. We take advantage of these outstanding properties in our new helmet shell, where minimum weight and maximum protection are required.

Lines in motion

-

Pro Dry

PRO DRY is a high-quality coating for lines. The PFAS-free coating provides outstanding hydrophobic and oleophobic protection, enabling the lines to permanently repel water, oily substances, and dirt. It also optimizes their handling and service life.

-

Coating

The line’s textile fibers are protected by a coating, increasing its service life and improving its handling. The abrasion resistance and stiffness can be specifically adjusted. Where necessary, the coating is supplemented with components for UV protection.

-

Spliceact

The product attribute SPLICEACT guarantees that a line offers outstanding splicing properties thanks to the balanced ratio of yarns used in conjunction with the design parameters.

-

Stretchact

STRETCHACT indicates lines that have been stretched to make them stronger and reduce their elongation. The natural properties of the fibers are also anticipated so as to guarantee products with permanent length stability.

-

Shrinkact

SHRINKACT indicates the use of a shrinking process that gives the lines far higher elongation than the raw yarn. The process also homogenizes the elongation values.

-

Thermo Shield

Thermo Shield describes a thermal treatment process that evenly and permanently anticipates the shrinkage of the yarns used. The process perfectly aligns the core and sheath yarns to achieve outstanding dimensional stability and thus guarantee the well-known suppleness.

-

Protact

PROTACT lines are characterized by outstanding resistance to mechanical strain thanks to their construction. The sheath structure guarantees excellent wear and abrasion resistance, significantly increasing the service life of the products.