Climbing Ropes—Made in Germany

If your ears are filled with the deafening sound of hundreds of bobbins with colorful sheaths dancing around white core strands, you are in the in-house rope production department at our head office in Isny im Allgäu. This is the heart and soul of EDELRID and the place where we combine 160 years of craftsmanship with care, innovation, and research to create high-end climbing ropes that are globally renowned for their safety, quality, and outstanding handling.

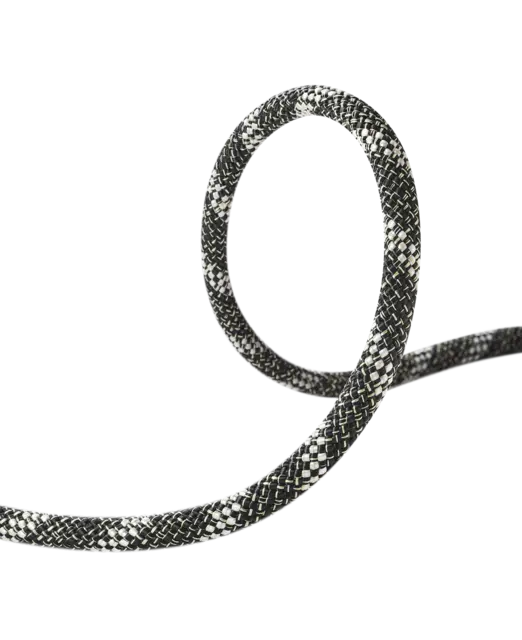

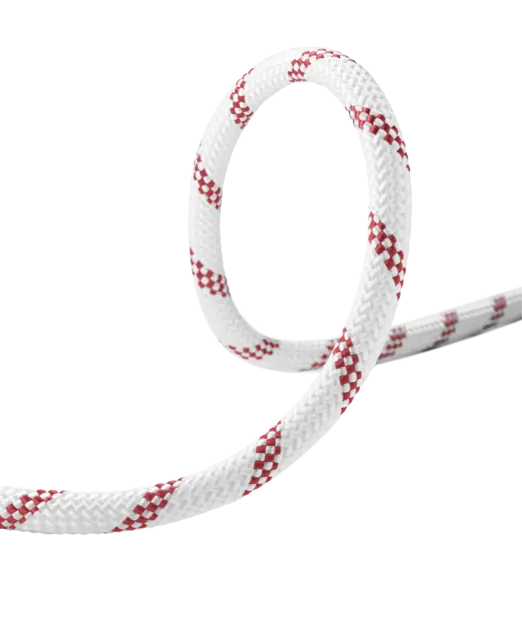

Climbing and mountaineering ropes are stretchable kernmantle braids made from wafer-thin polyamide fibers in a complex procedure. This design was first developed by EDELRID back in 1953 and is now used as standard.