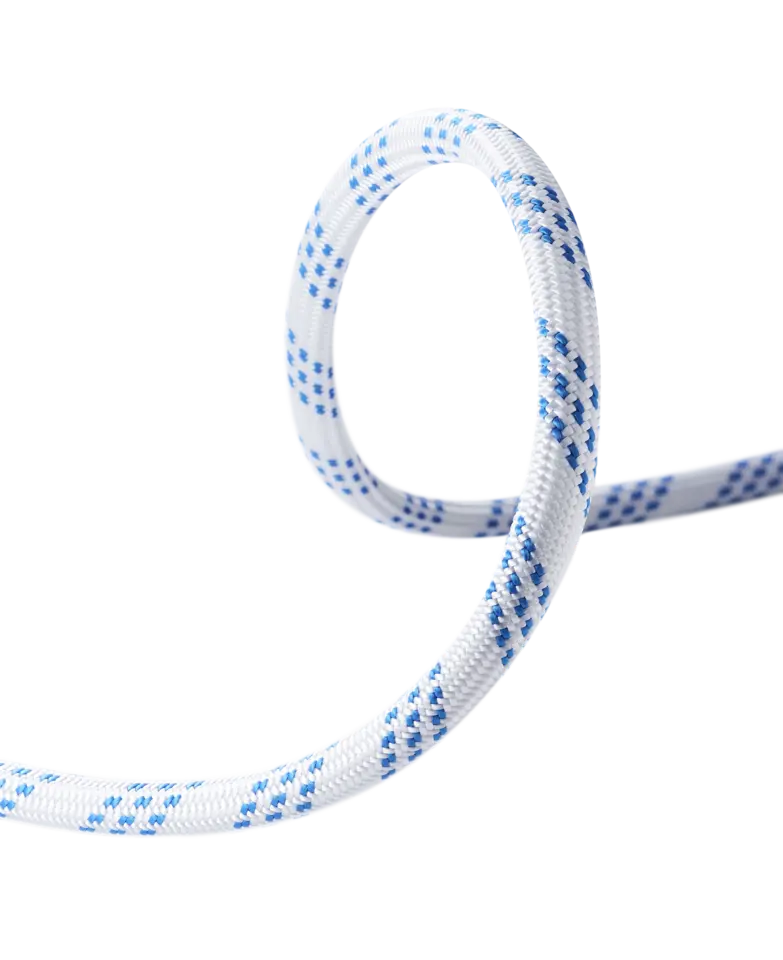

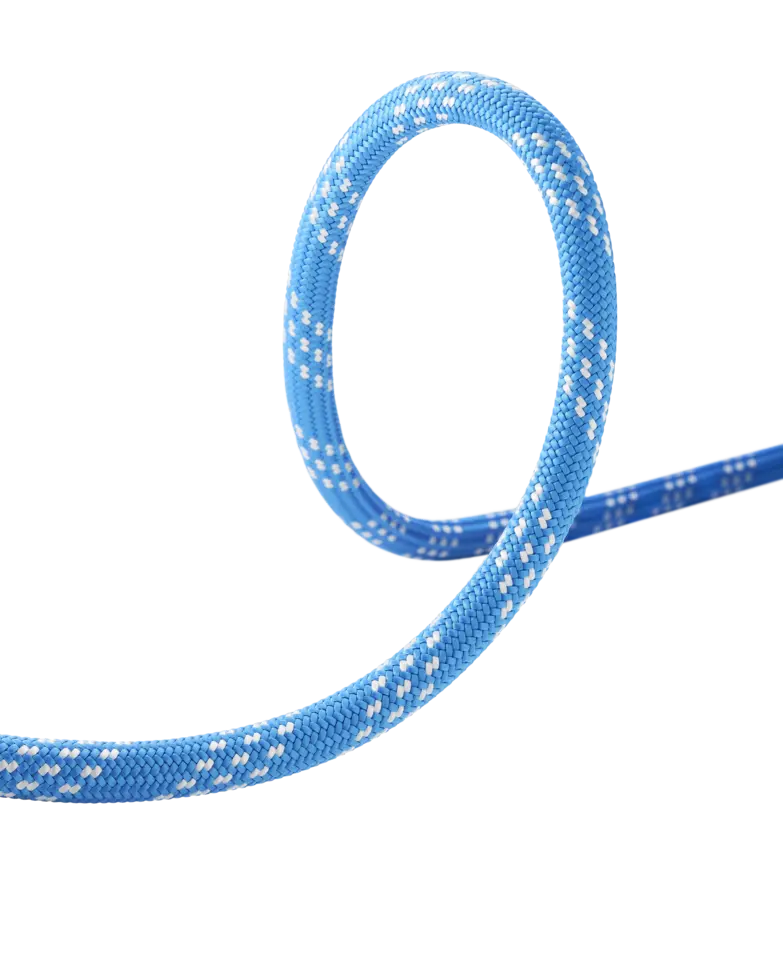

The PROSTATIC SYNCTEC is a static rope with a permanent, mechanically interconnected kernmantle that not only increases safety, but also extends the service life of the rope. The combination of a robust polyester sheath with a polyamide core ensures minimum elongation values and maximum abrasion resistance in use. These characteristics make the PROSTATIC SYNCTEC the first choice for demanding altitude and rescue operations, where an additional safety margin is beneficial.

-

Description

-

Features

- Thermo Shield treatment for pleasant handling

- Tracer threads in the rope sheath indicate the rope diameter

- Sync Tec technology for maximum dimensional stability and additional safety through permanent mechanical kernmantle braiding

- Multiple-wound polyester sheath results in elongation values of less than 3 % for greater precision when working

-

Technical information

- Diameter: 11 mm

- Knotability: 1

- Sheath proportion: 37 %

- Schrinkage H20: 2 %

- Weight per meter: 85 g/m

- Minimum breaking strength: 38 kN

- Static elongation: 2,5 %

- Minimum breaking strength in figure-of-eight knot: 22 kN

- Certification: EN 1891 Typ A

- Material: Polyester / Polyamide

-

EDELRID technologies

-

PDF downloads

-

Safety instructions & manufacturer information

- This product is part of personal protective equipment (PPE) and/or warnings and safety information are available for this product. Please refer to the instructions for use.

- Manufacturer: EDELRID GmbH & Co. KG | Achener Weg 66 | 88316 Isny i. A. | Germany | www.edelrid.com

The PROSTATIC SYNCTEC is a static rope with a permanent, mechanical core-sheath connection. This not only increases safety, but also extends the service life of the rope. The combination of a robust polyester sheath with a polyamide core ensure minimal elongation values and maximum abrasion resistance in use. These properties make the PROSTATIC SYNCTEC the first choice for demanding high-altitude and rescue operations where an additional safety reserve is an advantage.

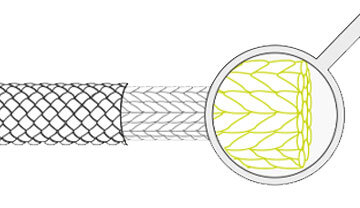

Sheath fanned

In this process, the yarns are wound in parallel on bobbins without twisting. Because the fibres are processed in parallel, maximum fibre utilisation is achieved and the technical values in terms of maximum breaking forces are the highest achievable. The only disadvantage is the somewhat lower abrasion resistance than with twisted constructions.

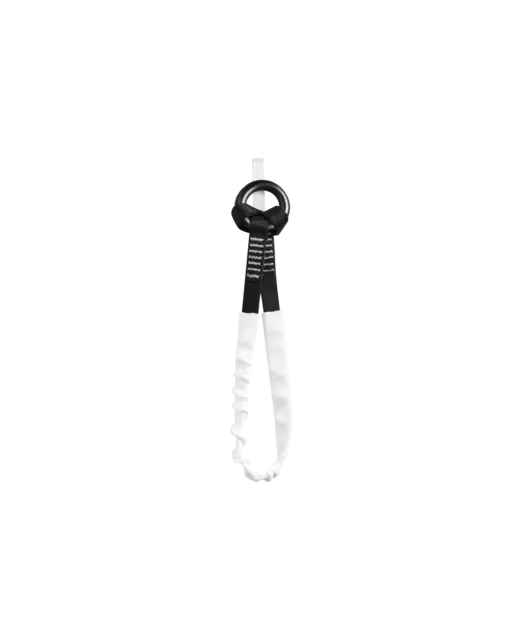

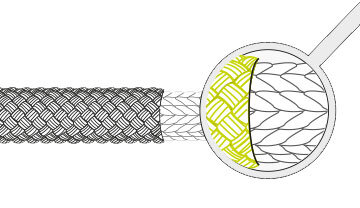

Core Twisted

The standard process for making core inserts. Depending on the respective construction, 3 basic twines (possibly 5 or 6) are twisted to form a core. In static ropes, 13 - 22 of these core plies form the load-bearing core.