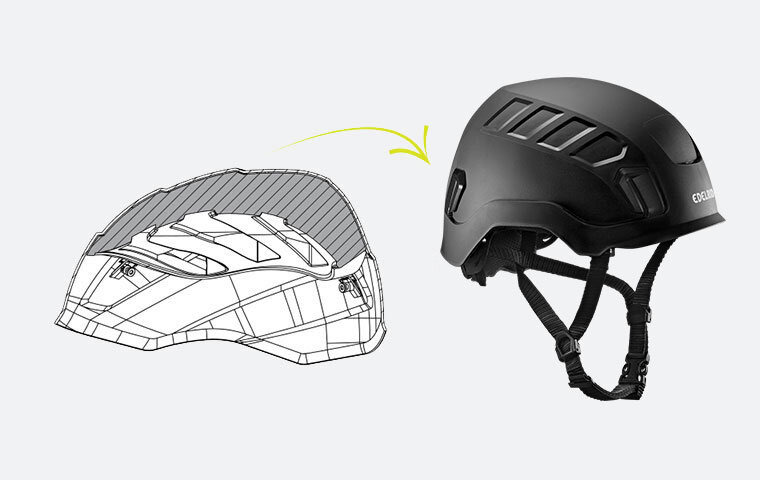

In-Mold (Softshell) Helmets

Helmets with in-mold technology have a thin outer shell made of polycarbonate, which is firmly connected to a shock-absorbing expanded polystyrene (EPS) core. The energy is absorbed through the deformation of this core. The polycarbonate shell protects the EPS core from damage and distributes the resulting force over a larger area. Depending on the model, the outer shell may only partially cover areas of the head. Softshell helmets are particularly light, but also less robust than other helmet types. They can therefore be damaged if carelessly subjected to loads, for example, by accidentally sitting on them. Their low weight and excellent ventilation properties make these helmets the number one choice for tree care.