The climbing season is over? Or you are just starting to prepare for the next adventures? There are many good reasons to check, maintain and, if necessary, repair your equipment. This also applies to hard goods such as carabiners. The use in sports climbing, multipitch tours or mountaineering etc. leaves its traces, but a perfect functionality for upcoming adventures should be guaranteed; no matter if you are out in snow and ice or if you "only" want to store the equipment for winter.

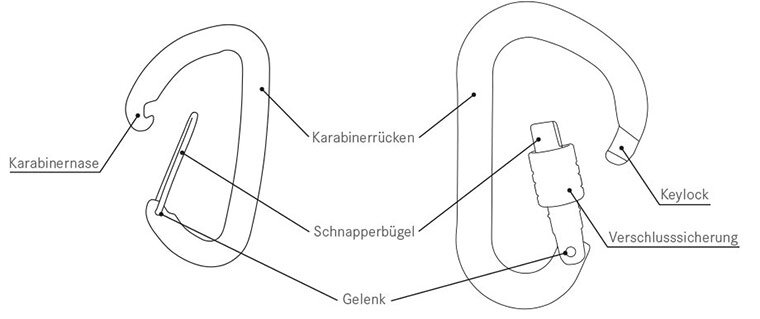

Abbildung 1, Carabiner as a classic gate (/wire) and locking version

Inspection instruction

For each PPE product (Personal Protective Equipment) there are inspection instructions that can be assigned based on the European standards. These are either indicated directly on the product or can be found in the user manual and provide a guideline for inspecting the product

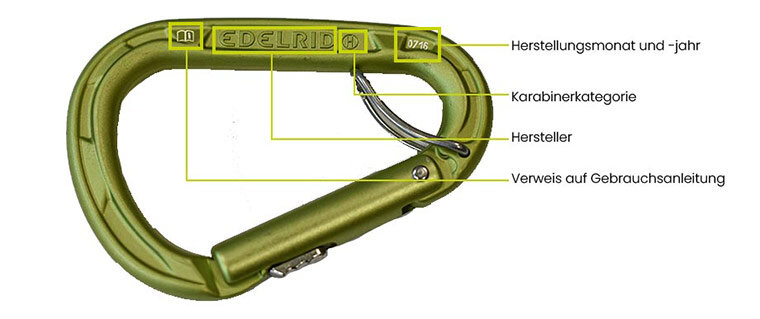

Markings

On each karabiner the following must be obligatorily marked: Manufacturer, carabiner category (except basic carabiner = gate), minimum strength values in kN (longitudinal direction with closed gate, longitudinal direction with open gate and cross direction), reference to the user manual as well as the CE marking with four-digit identification number. In addition, the month and year of manufacture are often indicated, but this is only mandatory for textile components.

Inspection of carabiners

Carabiners undergo both a visual inspection and a mechanical functional test. Depending on the condition or damage of the carabiner, repair is recommended, but there are also scenarios that require the immediate discarding of the carabiner. Basically, carabiners can be divided into three categories based on their condition:

- Flawless: The carabiner is free of sharp edges, corrosion and/ or rust. All axles and joints are working properly. (Note: Products containing screws that may be opened by the user according to the manufacturer's instructions must be checked for the correct torque of the screw). Marking is legible and unambiguous.

- Repair necessary: Joints or axles are blocked or run stiffly. The carabiner has rounded, slightly worn areas, visible notches and/or the locking mechanism runs sluggishly. Also, if axles squeak during operation, this is a clear indication of lack of lubrication.

- Discard: The leaf spring of the gate is broken. The locking mechanism is faulty. Clear signs of corrosion. Deformation is present. Detectable cracks or fractures. Abrasion of material (mostly in the apex of the carabiner) is ≥ 25 %. There are sharp edges. The manufacturer's service life specification has been exceeded.

Tips and tricks for the maintenance of carabiners

Not every defect on carabiners is a clear criteria for their discarding. Many minor defects can be repaired to reduce progressive wear or to maintain the safety of the product. As in all cases of PPE assessment, the same applies here - repair only if the facts are clear. In case of doubt, the product should be discarded!

Carabiners and metal components with joints must be clean and dust-free, carabiner gates and locking mechanisms must lock completely automatically, and mechanical joints must be easy to operate. If this is not the case, joints that are difficult to operate can often be loosened again by cleaning and lubrication.

Cleaning is initially possible with water, soft brushes and cloths. If this is not sufficient, compressed air, soft wire brushes and cleaning sprays can be used. CAUTION: when using cleaning sprays, ensure (e.g. by removing or, if this is not possible, covering) that textile components do not come into contact with the cleaning spray.

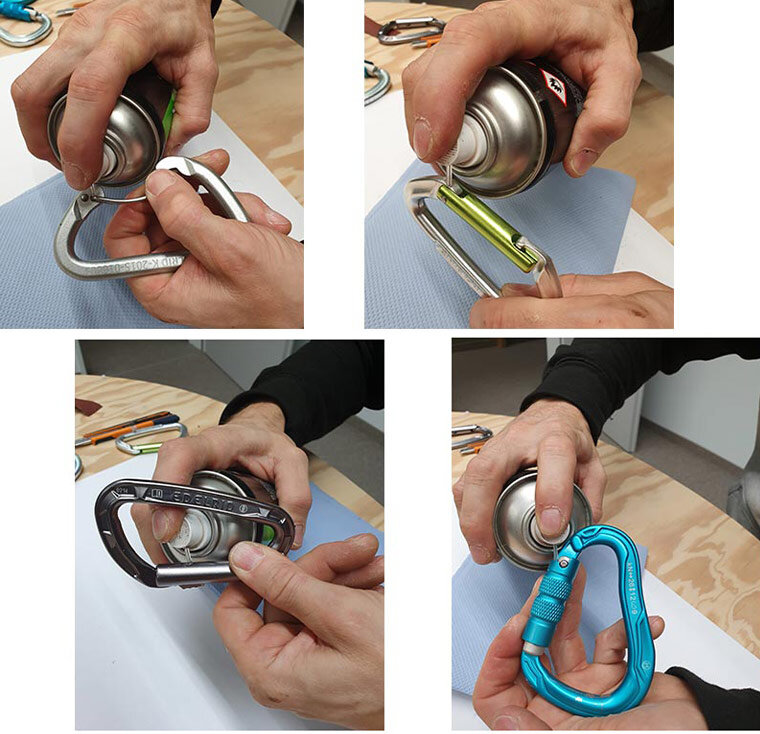

Afterwards, all joints must be lubricated again with acid-free lubricants (e.g. Teflon-based). Joints that run dry will cause permanent damage to the axles. If flash rust or corrosion is present that cannot be removed, the product should be discarded.

In the following we show which steps are important when cleaning and/or maintaining carabiners and metal components:

Abbildung 11, Cleaning the carabiner with water and brush

Abbildung 12, Removal of flash rust from steel carabiners with copper brush

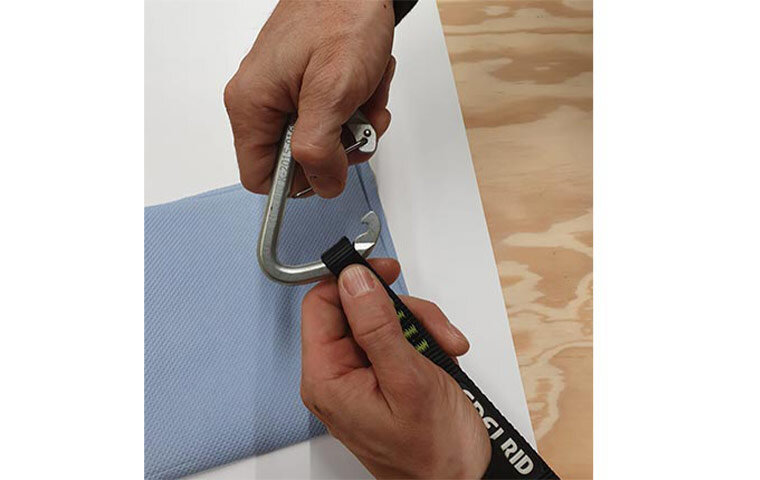

Abbildung 13, Remove or protect textile components before lubricating

Abbildung 14, Lubricating the joints with acid-free lubricants (Collage aus den Bildern: Gelenke ölen Drahtschnapper, Gelenke ölen Schnapper, Gelenke ölen Slide-Verschluss, Gelenke ölen Triple Lock)