When climbing mountains, you often ask yourself the same questions. How strenuous is it? How much further is there to go? Can I manage it? Will the equipment hold up reliably? We dealt intensively with the latter question in particular during our first cadre measure in the picturesque Allgäu region.

On Monday morning, we gather at the EDELRID headquarters in Isny, where we are first given an overview of the days ahead and EDELRID's corporate philosophy. First there is a theoretical introduction, followed by a practical tour of production, especially rope manufacturing.

We probably never imagined how many steps it takes to make a rope. In my head, I imagined that a machine like a knitting machine would simply process long threads into ropes. But we learn that ropes are not knitted or woven, but braided - even if we continue to consistently confuse the two. Furthermore, a single thread is not simply used. Instead, polyamide fibers, for example, come together in pairs or groups of three and are loosely knitted into large tubes (yes, they are actually knitted first) and then shrunk in a so-called autoclave (a kind of large oven). This allows them to stretch and contract better later under dynamic loads. As Daniel says: “Just like a perm”. If you want to find out more, you can read the details in the EDELRID Knowledge Base.

We are thrilled and stop at every single step of the process. We are allowed to touch everything while Daniel passionately explains to us why this spool turns in a certain direction or why this core fiber has a certain color. We also take a look at hardware development and gain insights into areas such as rope access technology and quality assurance. Did you know that every meter of rope is checked by hand to make sure everything is perfect? Of course, we were already aware that our equipment is reliable, but now we understand why and can appreciate the enormous effort that goes into ensuring that every carabiner and every rope performs as promised.

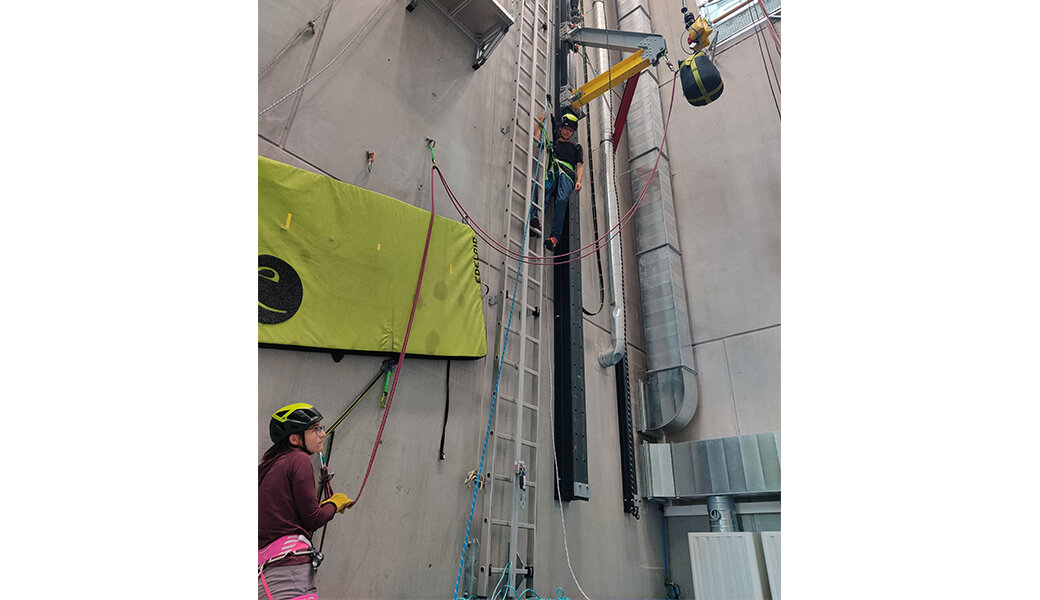

We then have lunch together before moving on to the so-called Spielraum. Two technical systems are available there, with which we can drop a tire and sandbags of different weights to the ground in a controlled manner. We start our belay training. However, not like outside on the rock, where a generous safety distance must always be maintained. Instead, we ask ourselves questions like: Will the belay hold if I fall into the first exe after standing and have only clipped a half-rope there? The short version of our answer: probably not.

We also improve our belaying skills and test which methods can be used to belay falls in the softest and shortest way. We also analyze how much weight acts on the redirection in the event of a fall. From now on, we no longer have to ask ourselves whether our belay partner can hold a fall.

In the evening, Dörte and Daniel welcome us to their charming half-timbered house, which offers us a really cozy base camp. We watch the Olympics together and cause chaos in the kitchen while cooking before heading to our unusual sleeping areas. Two of us spend the night in the portaledge hanging out of the kitchen window, while one of us sleeps in a bed that Tommy Caldwell slept in a few days ago! This motivates us to climb even harder the next day.