Learn about the basic details of braided ropes and appreciate this unique and beautiful craft.

“I don’t know what rope I use. A rope is a rope, right?”. To those of us who spend every day thinking of ways to make climbing ropes safer, lighter, more sustainable, more durable, or more affordable - or how to achieve a combination of these improvements by understanding, reviewing, and tweaking the tiniest details in the production process, a statement like this is like a kick in the nuts. Join us in this series of articles to get enlightened, learn about the differences with regard to what is probably one of the most important pieces of gear you own, and appreciate the wonderful craft of braiding.

Let me start by getting something off my chest: Ropes are braided not woven!

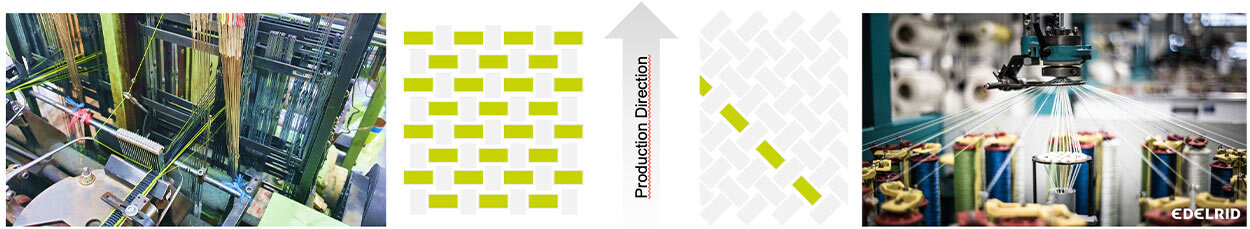

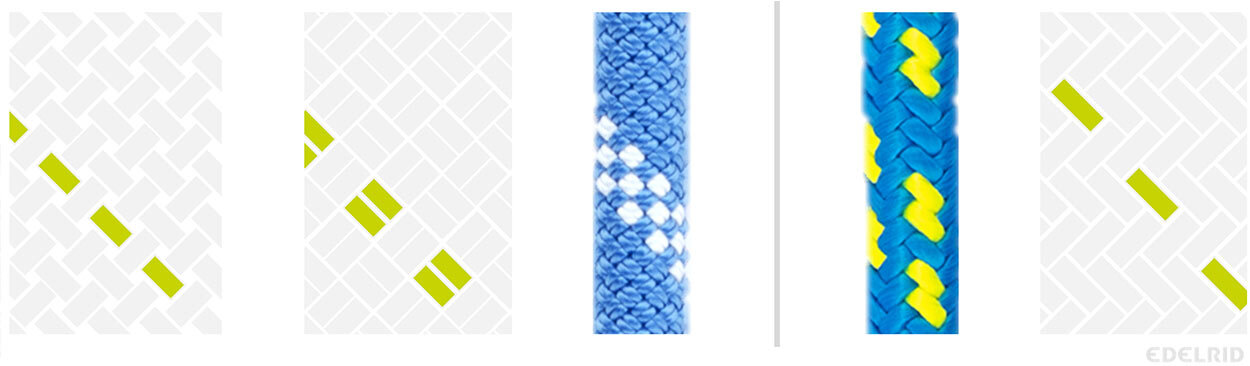

I realize that this is a minor detail, but if you want to truly dive into the world of ropes and not disqualify yourself in some nerd talk, you need to get this straight. Every time I hear someone use the term “weave” in the context of ropes, I get a nervous twitch. It is somewhat understandable, perhaps. The difference may seem small but actually involves two completely different machines and processes. So, in brief: braiding is the regular interlacing of several strands of flexible material. The main differences to weaving are that in braiding the threads are not fed at zero or right angles to the main production direction and you have a single coherent thread system as opposed to several independent ones as in weaving.