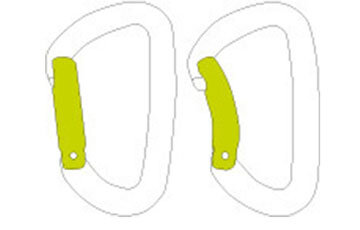

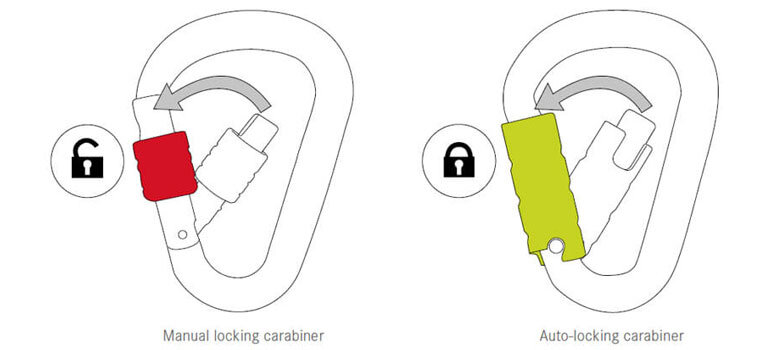

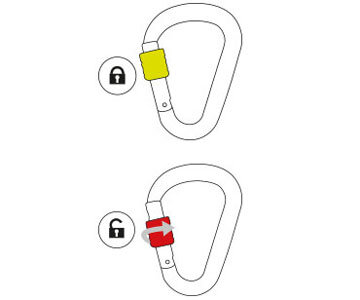

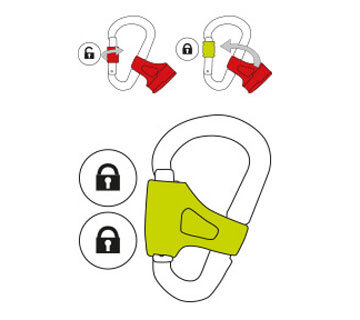

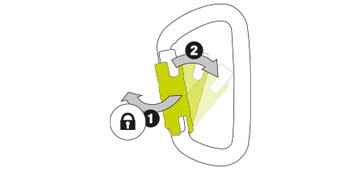

Carabiners are used in a wide variety of situations. This is why there are so many different types available. New models are introduced to the market every year. Locking carabiners, non-locking carabiners, non-load-bearing accessory carabiners, quickdraw carabiners, HMS carabiners, screwgates, twistlocks... sometimes it's hard to keep track. There are three main types of carabiner:

1. non-load-bearing (accessory) carabiners, 2. basic or normal carabiners (often referred to as non-locking carabiners) and 3. locking carabiners.