MATERIALS AND CONSTRUCTION

Four materials are used for the textile fibers in ropes, slings, and accessory cords:

Polyamide (PA) is the most widely used material. At 15–30%, it has the highest elongation at break of the four materials but only a medium tensile strength of 800 N/mm2. This is why—compared to high-strength materials such as Dyneema® (UHMWPE) or aramid—more material has to be incorporated into products made from polyamide to achieve the same strength. It is both intertwined into ropes and accessory cords with a kernmantle construction and interwoven into webbing constructions.

Polyester has the same breaking strength as polyamide and a lower elongation at break (10–20%). It is slightly more abrasion resistant and primarily used in sewn and non-sewn formats in webbing constructions.

Dyneema® is the brand name for ultra-high-molecular-weight polyethylene (UHMWPE). It is extremely strong with a tensile strength of 3,400 N/mm2 but has a very low elongation at break of 3.8%. As the surface is very smooth, knots slip easily.

Dyneema® is used in stitched slings and accessory cords. As it is high-strength, the slings offer the necessary breaking load even with a very small diameter.

Aramid is an aromatic polyamide, the properties of which differ from those of its aforementioned relative. It is extremely strong with a breaking strength of 3,300 N/mm2 but has a low elongation at break of 3.5%. The fibers are golden yellow and are mainly used to create the core of accessory cords.

ROPES AND WEBBING USED

The tests were performed using two ropes and all common types of EDELRID webbing, accessory cords, and slings.

The Apus Eco Dry is a thin, 7.9 mm half and twin rope with a meter weight of 44 g/m. It withstands nine standard falls as a half rope and 30 as a twin rope.

The triple-certified Swift Eco Dry is 8.9 mm thick and has a meter weight of 52 g/m. It withstands seven standard falls as a single rope and 22 as a half or twin rope.

The webbing materials tested were polyamide webbing with a width of 16, 19, and 25 mm, 12-mm-wide Tech Web composite fabric webbing with a polyamide sheath and a Dyneema® core, and Dyneema® webbing with a width of 8 and 11 mm. However, despite the common name, the 11 mm Dyneema® webbing is actually composite fabric webbing that contains 57% polyamide.

The accessory cords used were a 6 mm accessory cord made of polyamide, an accessory cord with a Dyneema® core and polyester sheath (Hardline), an accessory cord with an aramid core and a polyamide sheath (Aramid Cord), and an accessory cord with a polyamide core and an aramid/polyamide sheath (Rap Line Protect Pro Dry).

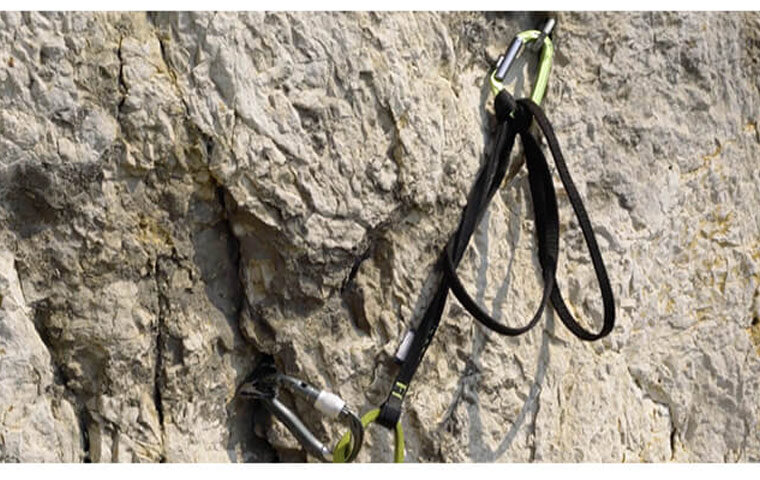

The belay station setups with sewn material were created using 120-cm-long slings made from the 16 mm polyamide, Tech Web composite fabric, and 8 and 11 mm Dyneema® webbing described above, as well as the Aramid Cord.

TEST SETUP

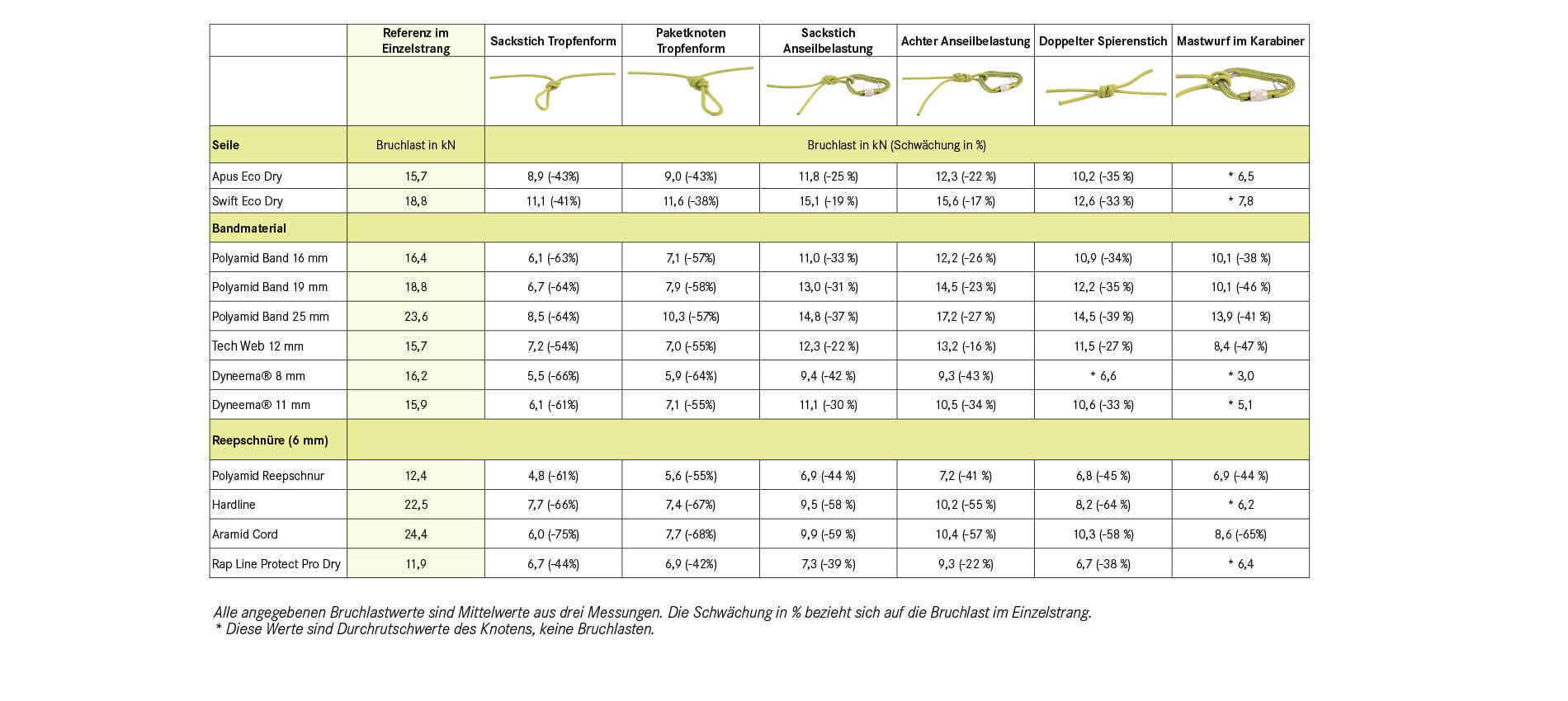

To assess the extent to which the knots reduces the strength of the materials, the breaking load and elongation of the unknotted materials were first determined as points of reference in accordance with EN 566 and EN 565 using sheaves.

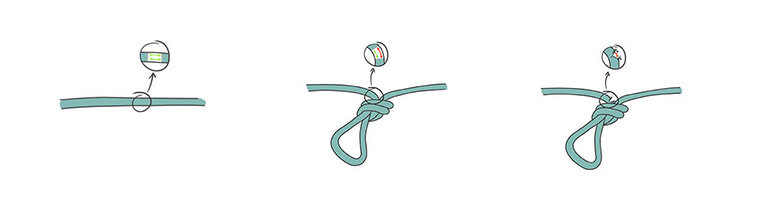

The materials were subsequently tested with a range of common mountaineering knots: the flat offset overhand bend and double flat overhand bend, the offset overhand bend and figure-eight loop subject to roping-up load, the double fisherman's knot as a connection between two ends and the clove hitch on a carabiner.

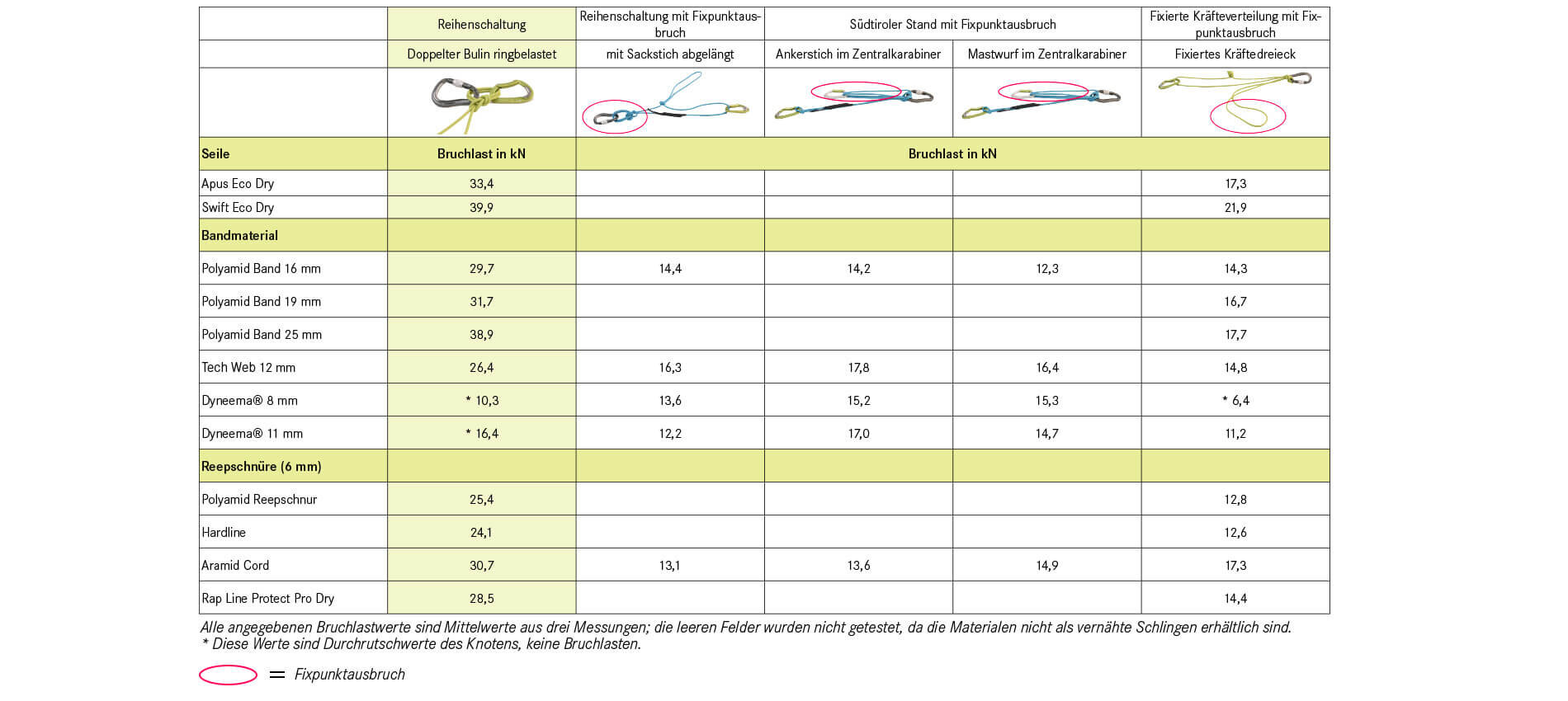

Tests were also performed on several knot combinations, as used on belay station setups or as subjected to loads at the belay if an anchor blows.

- The strength of a Bowline on a bight eyelet, as subjected to a load when connected in series.

- Anchor blowout when connected in series with a Bowline on a bight and shortened with an offset overhand bend.

- Anchor blowout with a South Tyrolean belay in which the double-strand section of the sling bears the load. If the other anchor blows, the strength is definitely higher due to the load being distributed across four strands. Two versions were tested: one with a girth hitch on the central carabiner and one with a clove hitch on the central carabiner.

- Anchor blowout with a fixed distribution of forces consisting of unsewn material connected with a double overhand bend and a girth hitch on the central carabiner.