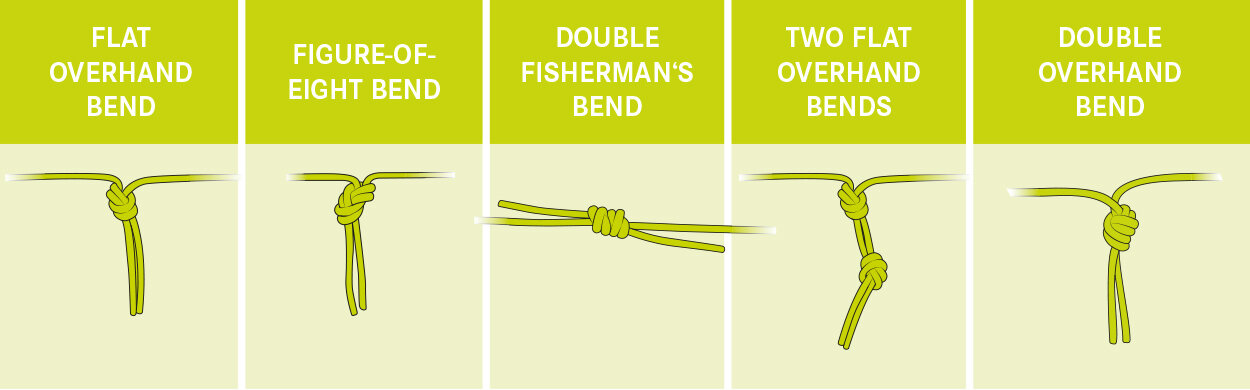

Which knots can be used to connect ropes and what are their advantages and disadvantages in different situations?

Knots for joining ropes when rappelling. There are several scenarios in which ropes need to be joined when rappelling: Firstly, to use the full length of double ropes. Secondly, to make a rope longer during rescue maneuvers. Or thirdly, when climbing using a single rope then rappelling by combining this with a thin take line. The discussion as to which knots are best for connecting ropes is long standing and the answers differ depending on the country, club/association or mountain sport discipline, as well as in the field of professional work at height.

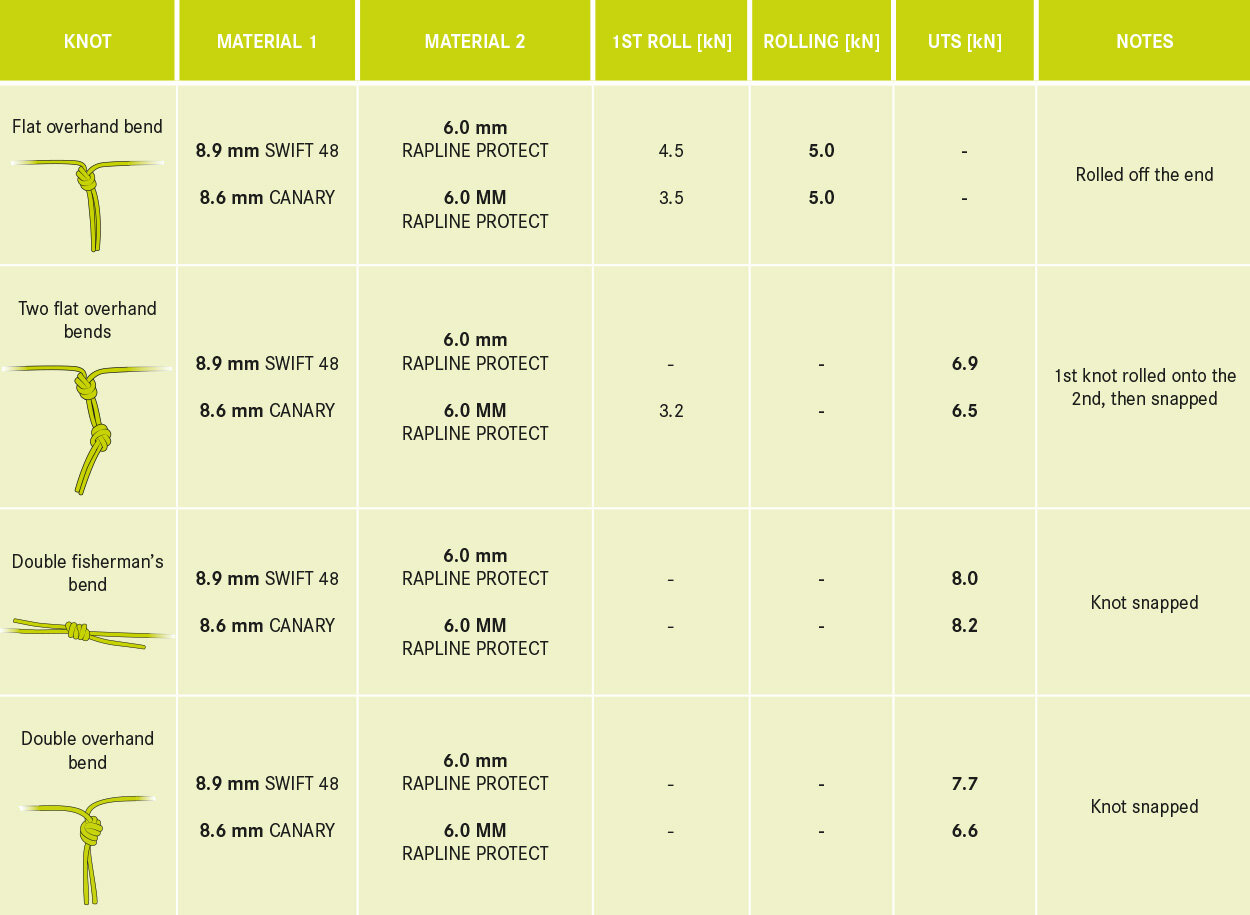

The article below looks at the strengths, advantages and disadvantages of the most commonly used knots for connecting ropes as well as what happens when ropes of different diameters are connected.

Loads when rappelling

To assess the suitability of a knot for connecting ropes, the first question is which forces arise while rappelling. The exact force depends on the weight of the person rappelling, the type of rope, and the behavior while rappelling.

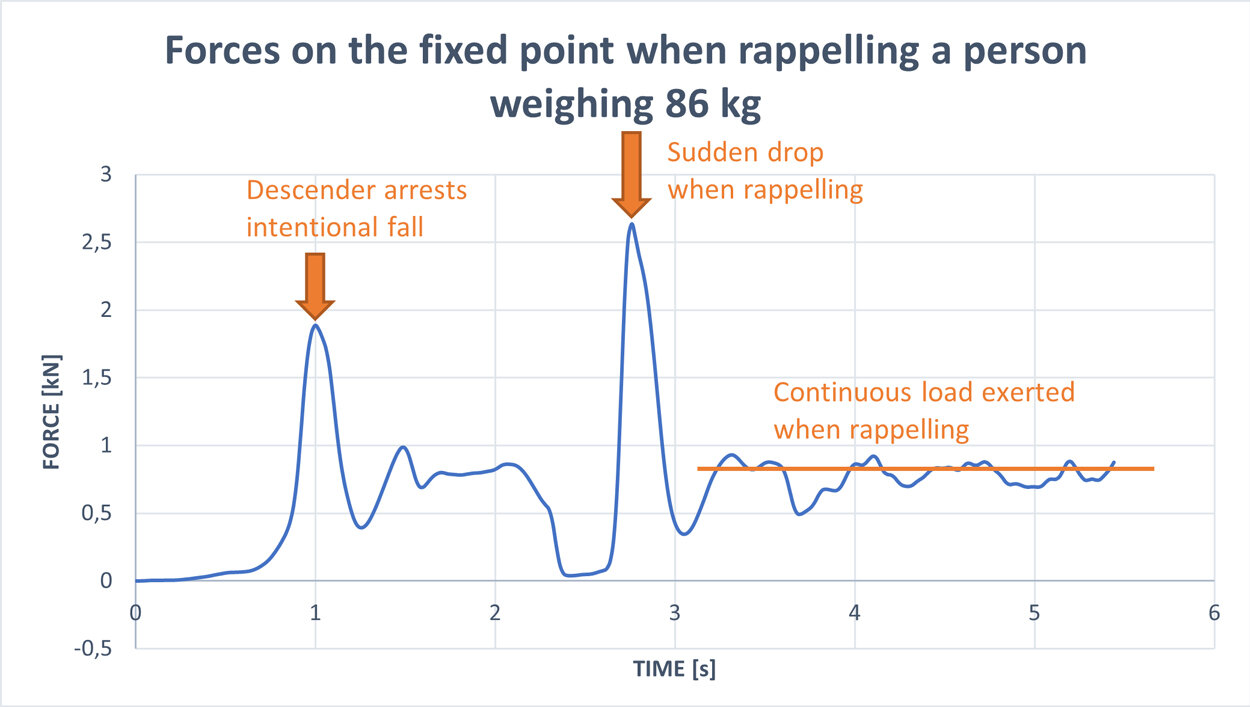

Tests were performed to measure the forces exerted on the directional anchor when a person weighing 86 kg is rappelling. Figure 1 shows an example of a force-time curve. Brief force peaks occur when someone intentionally makes the descender abruptly arrest them or severely jerks (suddenly drops) while rappelling. These force peaks reach a maximum of 2.6 kN, approximately three times the body weight of the person rappelling. Higher forces are almost only possible if a descender were to fully arrest an actual fall. The tests were repeated with various belay devices and ropes, and the forces were not even exceeded when using a rope with low elongation pursuant to EN 1892. With smooth rappelling, the forces remain similar to the body weight at 0.9 kN. This differentiation makes sense as some knots that connect ropes have a tendency to roll when subjected to a constant force but, conversely, to tighten without rolling in the event of brief force peaks. Calculated for a person weighing 120 kg, a maximum force of 3.6 kN should be exerted on the directional anchor when rappelling freely and a maximum continuous load of 1.2 kN should apply. When using a single strand, the entire load is also exerted on the knot connecting the ropes. When double-strand rappelling, only half the load is exerted on the knot connecting the ropes.