Pulleys with an integrated rope clamp are certified to EN 12278 and EN 567 and developed to haul loads and for rescues. Both standards solely require static tests. Despite this, pulleys with an integrated rope clamp, such as the EDELRID SPOC, are increasingly being used for belaying or as a backstop on a fixed point when using a sliding rope. Such uses involve a risk of a fall damaging or, in the worst-case scenario, severing the rope. Whether or not the risk is acceptable depends on the users’ level of risk acceptance and their ability to consistently implement risk-mitigating measures.

If the rope is constantly pulled taut while belaying, the self-locking pulley is essentially subjected to a static load if the climber falls. If, however, the belayer does not consistently pull in the rope or if the climber moves too quickly, slack rope forms in front of the pulley, which is then subjected to a dynamic load in the event of a fall. The same scenario applies in the case of a sliding rope where a self-locking pulley is attached to a fixed point as a backstop. If the second climbs slightly quicker, slack rope forms in front of the pulley, which is subjected to a dynamic load in the event of a fall.

When used as a rope clamp, the relevant legal standard establishes that when subjected to a static load of 4 kN, the self-locking pulley must neither be deformed to an extent that restricts its functionality nor sever the rope. How should the risk of damage to the rope in the event of a fall on the pulley be assessed?

What is acceptable?

Self-locking pulleys are developed for static loads. However, dynamic loads that can damage ropes occur during belaying use or when attached to a fixed point as a backstop. As a result, the instructions for use do not allow such usage. Products should always be used in line with the manufacturer’s specifications in the user manual. When assessing the use for belaying or as a backstop on a fixed point, the rope condition that the user is willing to tolerate following a fall is a key consideration. If belaying is regarded as an emergency system intended to prevent a complete fall, a ripped sheath may be tolerable. If falling is part of the sport and the gear is intended for long-term use, sheath damage is no longer acceptable. The following test results should make it easier to assess the different uses.

Test method

Two test scenarios were used:

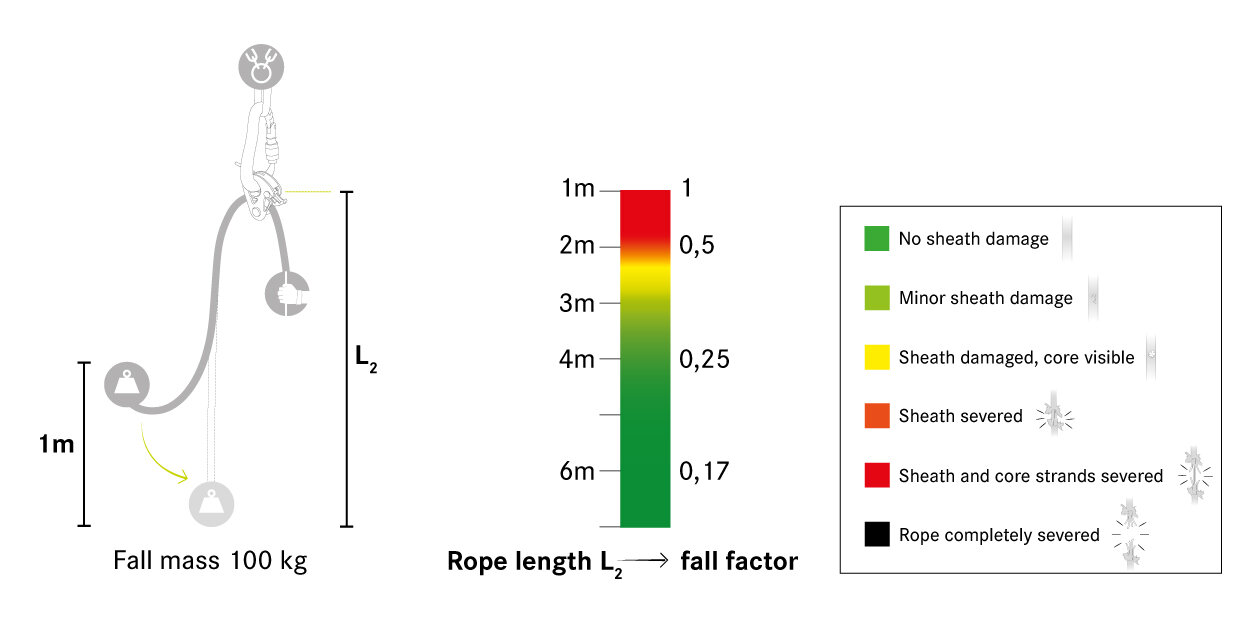

- A fall height of 1 m with a variable distance between the rope and the fixed point

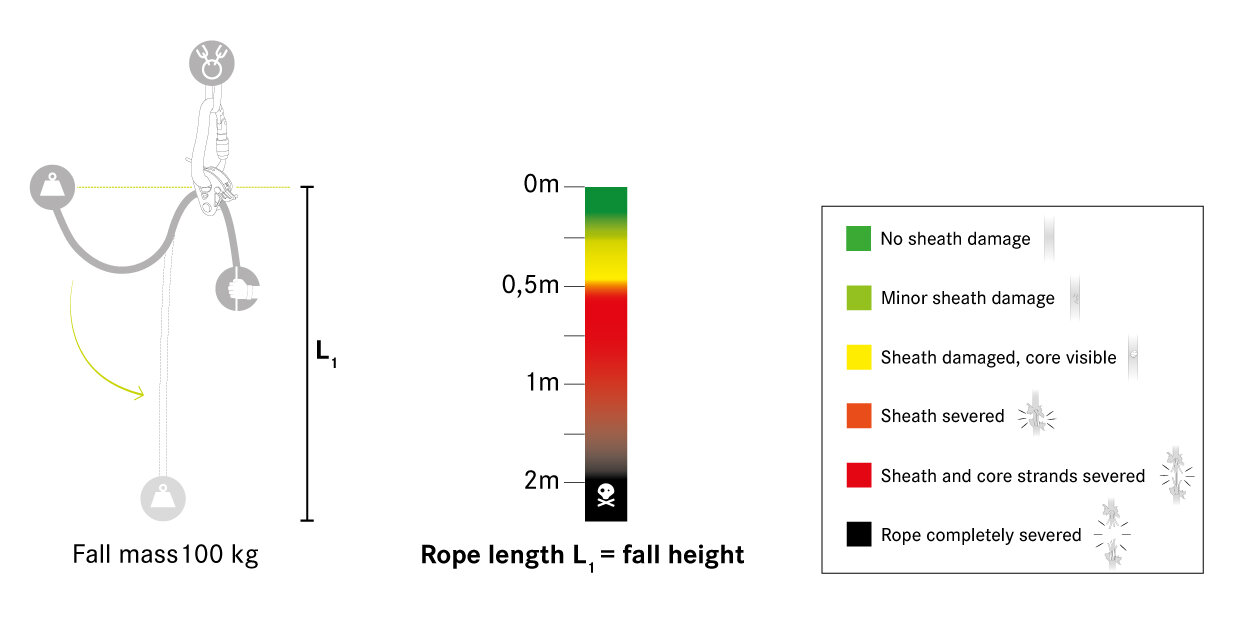

A 100 kg sandbag falls on the SPOC self-locking pulley from a height of 1 m and at an ever greater distance from the fixed point. - Different fall heights with a fall factor of 1

A 100 kg sandbag falls on a SPOC self-locking pulley that is clipped to a fixed point from different fall heights but with a consistent fall factor of 1.

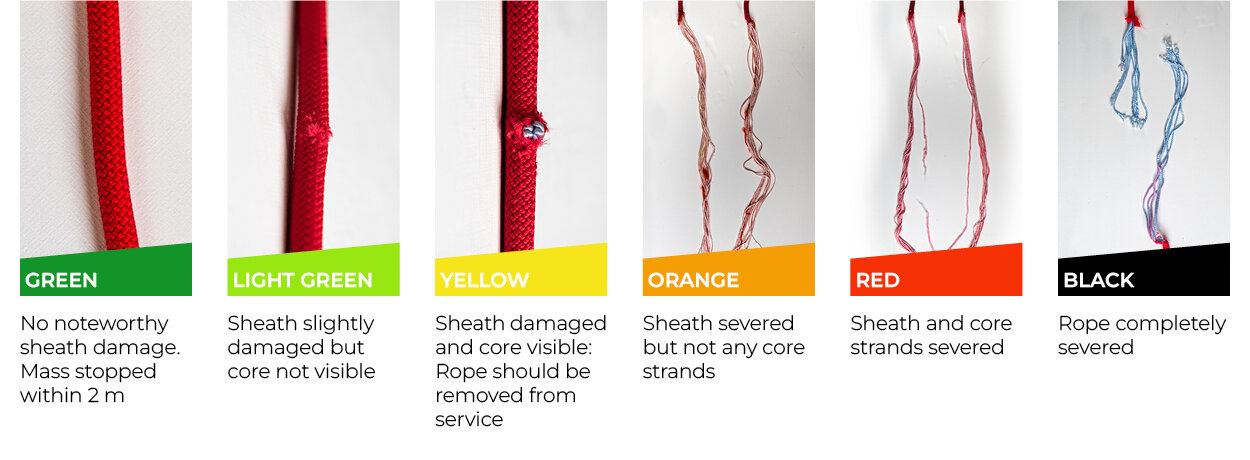

The condition of the rope following the fall was assessed and the results were categorized based on the following descriptions: