Working time span and temperature range

The avalanche airbag system must fulfill the requirements with regard to activation and inflation without external support (e.g., power supply, pressure support) after at least 24 hours at -30°C.

The avalanche airbag system must fulfill the requirements with regard to deployment and inflation and must not show any signs of damage within the manufacturer-specified temperature range or between -30°C and +50°C (whichever the greater extremes).

Electrically operated avalanche airbag systems must indicate when the battery is low. On reaching this state, it must still be possible to deploy the avalanche airbag systems for at least 6 hours.

Number of deployments

The avalanche airbag system must withstand twice the rated number of deployments specified by the manufacturer. The rated number of deployments must be at least 20.

Pressure testing

All components of the airbag system that are pressurized when fully inflated must withstand the operating pressure plus 0.1 bar for at least 30 minutes without showing any signs of damage.

Impact testing

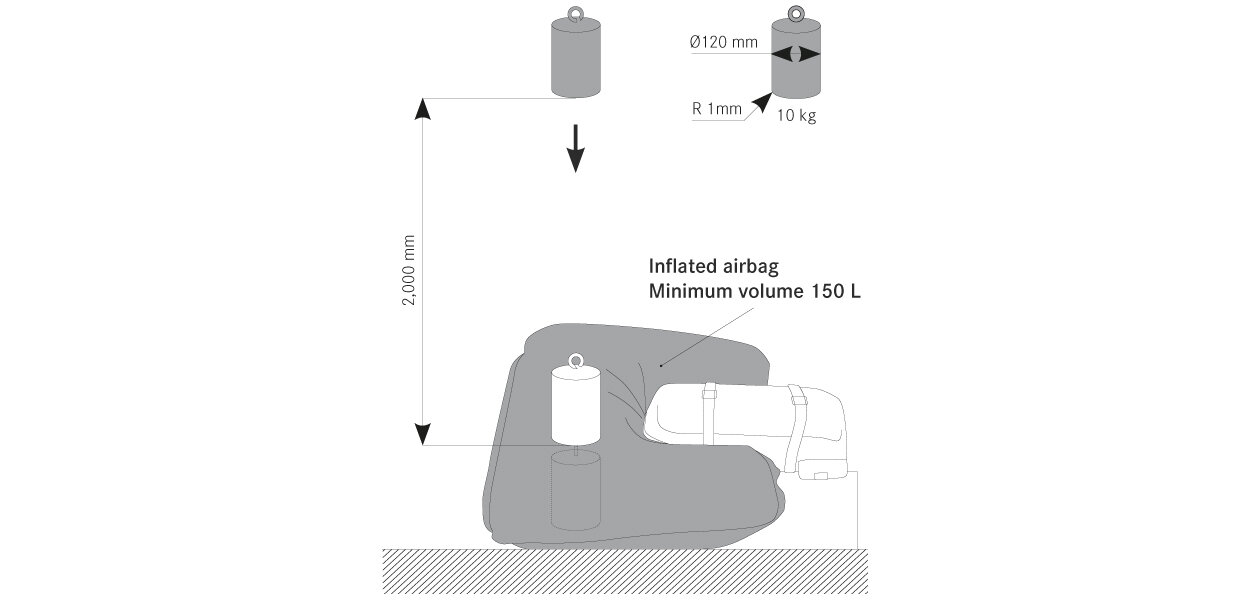

The fully inflated avalanche airbag system must be placed on a hard, level, smooth surface with the airbag in contact with it.

An impact test must be performed by vertically dropping a 10 kg cylindrical steel weight with a diameter of 120 mm and an edge radius of 1 mm onto the middle of the fully inflated airbag from a height of 2 m. The airbag must withstand the test without any damage and fulfill the minimum volume requirement of 150 l.